2019

|

| 8. |  | L. McCourt; B. S. Routley; M. G. Ruppert; A. J. Fleming Resolution and Enhancement of Probes for Tip Enhanced Raman Spectroscopy Conference International Conference on Nanophotonics and Micro/Nano Optics (NANOP), Munich, Germany, 2019. @conference{McCourt2019,

title = {Resolution and Enhancement of Probes for Tip Enhanced Raman Spectroscopy},

author = {L. McCourt and B. S. Routley and M. G. Ruppert and A. J. Fleming},

year = {2019},

date = {2019-09-04},

booktitle = {International Conference on Nanophotonics and Micro/Nano Optics (NANOP)},

journal = {International Conference Nanophotonics and Micro/Nano Optics},

address = {Munich, Germany},

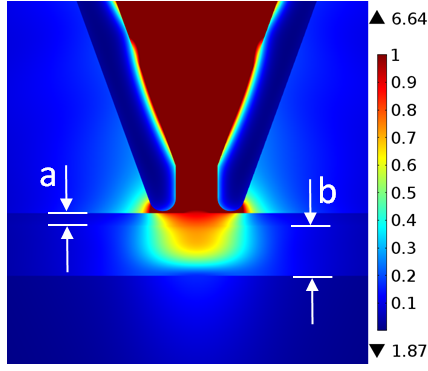

abstract = {Two photon apertureless nearfield lithography allows sub diffraction limited features for integrated circuit production. It involves exciting surface plasmons on a metallic atomic force microscopy probe, which generates an enhancement of the localised electric field, exposing a photoresist. Costing less than extreme ultra violet lithography, and reducing exposure from scattered light compared to one photon nearfield lithography, this technique is suited for device prototyping or low volume production. The work here considers the material and geometry of an ideal AFM probe in terms of resolution (producing the smallest features) and electric field enhancement.},

keywords = {AFM, Cantilever, Lithography},

pubstate = {published},

tppubtype = {conference}

}

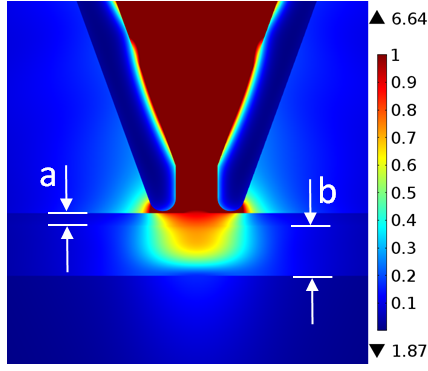

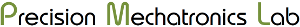

Two photon apertureless nearfield lithography allows sub diffraction limited features for integrated circuit production. It involves exciting surface plasmons on a metallic atomic force microscopy probe, which generates an enhancement of the localised electric field, exposing a photoresist. Costing less than extreme ultra violet lithography, and reducing exposure from scattered light compared to one photon nearfield lithography, this technique is suited for device prototyping or low volume production. The work here considers the material and geometry of an ideal AFM probe in terms of resolution (producing the smallest features) and electric field enhancement. |

| 7. |  | A. J. Fleming; O. T. Ghalehbeygi; B. S. Routley; A. G. Wills Scanning Laser Lithography with Constrained Quadratic Exposure Optimization Journal Article In: IEEE Transactions on Control Systems Technology, vol. 27, no. 5, pp. 2221-2228, 2019, ISBN: 1063-6536. @article{J19e,

title = {Scanning Laser Lithography with Constrained Quadratic Exposure Optimization},

author = {A. J. Fleming and O. T. Ghalehbeygi and B. S. Routley and A. G. Wills},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/02/J19e.pdf},

doi = {10.1109/TCST.2018.2836910},

isbn = {1063-6536},

year = {2019},

date = {2019-09-01},

journal = {IEEE Transactions on Control Systems Technology},

volume = {27},

number = {5},

pages = {2221-2228},

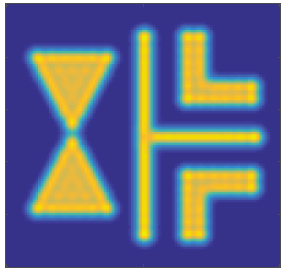

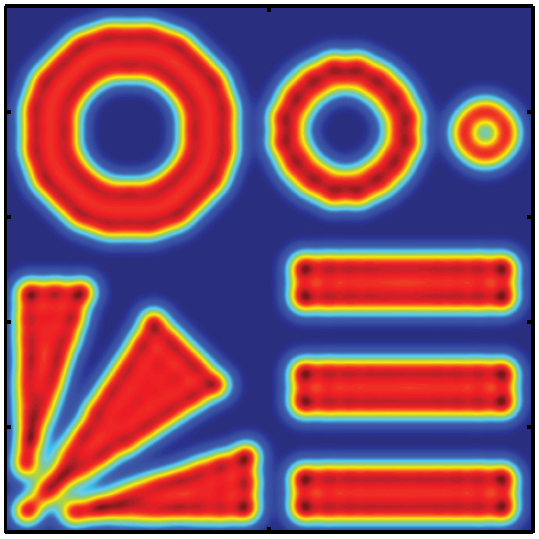

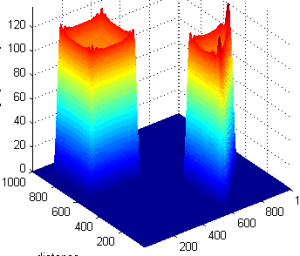

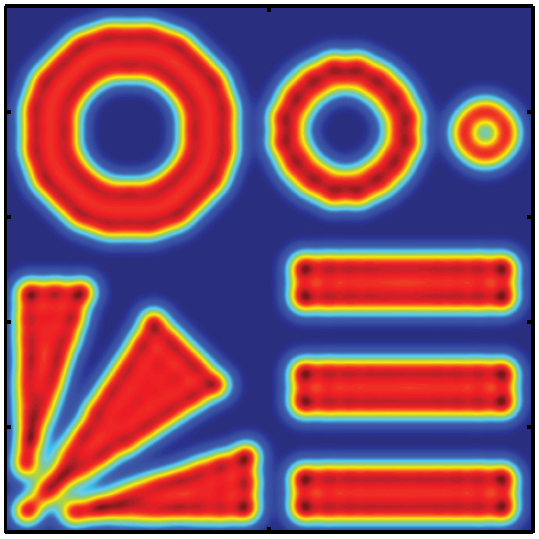

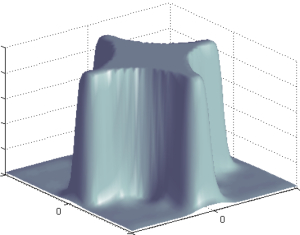

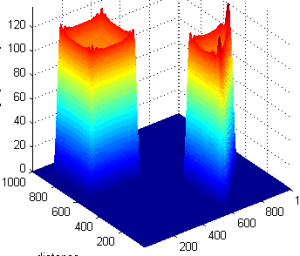

abstract = {Scanning laser lithography is a maskless lithography method for selectively exposing features on a film of photoresist. A set of exposure positions and beam energies are required to optimally reproduce the desired feature pattern. The task of determining the exposure energies is inherently non-linear due to the photoresist model and the requirement for only positive energy. In this article, a nonlinear programming approach is employed to find an optimal exposure profile that minimizes the feature error and total exposure energy. This method is demonstrated experimentally to create a features with sub-wavelength geometry.},

keywords = {Lithography},

pubstate = {published},

tppubtype = {article}

}

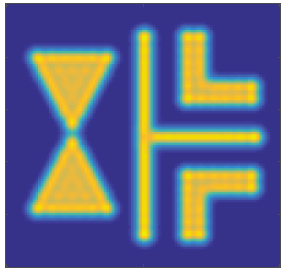

Scanning laser lithography is a maskless lithography method for selectively exposing features on a film of photoresist. A set of exposure positions and beam energies are required to optimally reproduce the desired feature pattern. The task of determining the exposure energies is inherently non-linear due to the photoresist model and the requirement for only positive energy. In this article, a nonlinear programming approach is employed to find an optimal exposure profile that minimizes the feature error and total exposure energy. This method is demonstrated experimentally to create a features with sub-wavelength geometry. |

2018

|

| 6. |  | O. T. Ghalehbeygi; J. O'Connor; B. S. Routley; A. J. Fleming Iterative Deconvolution for Exposure Planning in Scanning Laser Lithography Proceedings Article In: American Control Conference, Milwaukee, WI, 2018. @inproceedings{C18c,

title = {Iterative Deconvolution for Exposure Planning in Scanning Laser Lithography},

author = {O. T. Ghalehbeygi and J. O'Connor and B. S. Routley and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/02/C18c.pdf},

doi = {10.23919/ACC.2018.8431550},

year = {2018},

date = {2018-06-27},

booktitle = {American Control Conference},

address = {Milwaukee, WI},

abstract = {Laser scanning lithography is a maskless method for exposing photoresist during semiconductor manufacturing. In this method, the power of a focused beam is modulated while scanning the photoresist. This article describes an iterative deconvolution method for determining the exposure pattern. This approach is computationally efficient as there is no gradient calculation. Simulations demonstrate the accurate fabrication of a feature with sub-wavelength geometry.},

keywords = {Lithography},

pubstate = {published},

tppubtype = {inproceedings}

}

Laser scanning lithography is a maskless method for exposing photoresist during semiconductor manufacturing. In this method, the power of a focused beam is modulated while scanning the photoresist. This article describes an iterative deconvolution method for determining the exposure pattern. This approach is computationally efficient as there is no gradient calculation. Simulations demonstrate the accurate fabrication of a feature with sub-wavelength geometry. |

2017

|

| 5. |  | O. T. Ghalehbeygi; A. G. Wills; B. S. Routley; A. J. Fleming Gradient-based optimization for efficient exposure planning in maskless lithography Journal Article In: Journal of Micro/Nanolithography, MEMS, and MOEMS, vol. 16, no. 3, pp. 033507, 2017. @article{J17j,

title = {Gradient-based optimization for efficient exposure planning in maskless lithography},

author = {O. T. Ghalehbeygi and A. G. Wills and B. S. Routley and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2017/09/J17j.pdf},

doi = {10.1117/1.JMM.16.3.033507},

year = {2017},

date = {2017-09-01},

journal = {Journal of Micro/Nanolithography, MEMS, and MOEMS},

volume = {16},

number = {3},

pages = {033507},

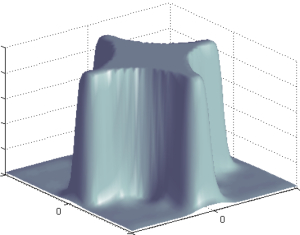

abstract = {Scanning laser lithography is a maskless method for exposing photoresist during semiconductor manufacturing. In this method, the energy of a focused beam is controlled while scanning the beam or substrate. With a positive photoresist material, areas that receive an exposure dosage over the threshold energy are dissolved during development. The surface dosage is related to the exposure profile by a convolution and nonlinear function, so the optimal exposure profile is nontrivial. A gradient-based optimization method for determining an optimal exposure profile, given the desired pattern and models of the beam profile and photochemistry, is described. This approach is more numerically efficient than optimal barrier-function-based methods but provides near-identical results. This is demonstrated through simulation and experimental lithography},

keywords = {Lithography},

pubstate = {published},

tppubtype = {article}

}

Scanning laser lithography is a maskless method for exposing photoresist during semiconductor manufacturing. In this method, the energy of a focused beam is controlled while scanning the beam or substrate. With a positive photoresist material, areas that receive an exposure dosage over the threshold energy are dissolved during development. The surface dosage is related to the exposure profile by a convolution and nonlinear function, so the optimal exposure profile is nontrivial. A gradient-based optimization method for determining an optimal exposure profile, given the desired pattern and models of the beam profile and photochemistry, is described. This approach is more numerically efficient than optimal barrier-function-based methods but provides near-identical results. This is demonstrated through simulation and experimental lithography |

2016

|

| 4. |  | A. J. Fleming; A. G. Wills; B. S. Routley Exposure Optimization in Scanning Laser Lithography Journal Article In: IEEE Potentials, vol. 35, no. 4, pp. 33-39, 2016, ISSN: 0278-6648. @article{J16b,

title = {Exposure Optimization in Scanning Laser Lithography},

author = {A. J. Fleming and A. G. Wills and B. S. Routley},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2016/08/J16b.pdf},

doi = {10.1109/MPOT.2016.2540039},

issn = {0278-6648},

year = {2016},

date = {2016-12-01},

journal = {IEEE Potentials},

volume = {35},

number = {4},

pages = {33-39},

keywords = {Lithography},

pubstate = {published},

tppubtype = {article}

}

|

| 3. |  | A. J. Fleming; A. G. Wills; O. T. Ghalehbeygi; B. S. Routley; B. Ninness A Nonlinear Programming Approach to Exposure Optimization in Scanning Laser Lithography Proceedings Article In: American Control Conference, Boston, MA, 2016. @inproceedings{C16d,

title = {A Nonlinear Programming Approach to Exposure Optimization in Scanning Laser Lithography},

author = {A. J. Fleming and A. G. Wills and O. T. Ghalehbeygi and B. S. Routley and B. Ninness},

year = {2016},

date = {2016-07-01},

booktitle = {American Control Conference},

address = {Boston, MA},

keywords = {Lithography},

pubstate = {published},

tppubtype = {inproceedings}

}

|

2015

|

| 2. |  | O. T. Ghalehbeygi; G. Berriman; A. J. Fleming; J. L. Holdsworth Optimization and Simulation of Exposure Pattern for Scanning Laser Lithography Proceedings Article In: IEEE Multiconference on Systems and Control, Sydney, 2015. @inproceedings{C15d,

title = {Optimization and Simulation of Exposure Pattern for Scanning Laser Lithography},

author = {O. T. Ghalehbeygi and G. Berriman and A. J. Fleming and J. L. Holdsworth},

year = {2015},

date = {2015-12-01},

booktitle = {IEEE Multiconference on Systems and Control},

address = {Sydney},

keywords = {Lithography, Optics},

pubstate = {published},

tppubtype = {inproceedings}

}

|

| 1. |  | B. S. Routley; J. L. Holdsworth; A. J. Fleming Optimization of near-field scanning optical lithography Proceedings Article In: Proc. SPIE Advanced Lithography, San Jose, CA, 2015. @inproceedings{D15a,

title = {Optimization of near-field scanning optical lithography},

author = {B. S. Routley and J. L. Holdsworth and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2015/05/D15a.pdf},

year = {2015},

date = {2015-02-26},

booktitle = {Proc. SPIE Advanced Lithography},

address = {San Jose, CA},

keywords = {Lithography},

pubstate = {published},

tppubtype = {inproceedings}

}

|