Biography

Yuen Kuan Yong received the B.Eng. degree (1st Class Hons.) in mechatronic engineering and the Ph.D. degree in mechanical engineering from The University of Adelaide, Australia, in 2001 and 2007, respectively. She was previously an Australian Research Council DECRA Fellow with the School of Electrical Engineering and Computer Science, The University of Newcastle, Australia. Her research interests include the design and control of nanopositioning systems, high-speed atomic force microscopy, actuation and sensing of microcantilever, finite-element analysis of smart materials and structures, MEMS and miniature robots.

Dr. Yong is a recipient of the 2008 and 2016 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM) Best Conference Paper Finalist Award, The University of Newcastle Vice-Chancellor’s Awards for Research Excellence and the Pro Vice-Chancellor’s Award for Excellence in Research Performance. She is an Associate Editor for the IEEE/ASME Transactions of Mechatronics, and the Frontiers in Mechanical Engineering (specialty section Mechatronics). She is also a steering committee member for the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS).

Awards/Fellowships

- 2016: Best Conference Paper Finalist Award at the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM).

- 2014: Vice-chancellor’s award for research excellence.

- 2014: Pro Vice-chancellor’s award for excellence in research performance.

- 2013: Australian Research Council DECRA – This award was highly competitive with a success rate of only 15.6%.

- 2012: University Postdoctoral Research Fellowship – one of the only four recipients at the University of Newcastle.

- 2008: Best Conference Paper Finalist Award at AIM – for the novel design and control techniques of nanopositioning devices.

Supervised Student Awards

- Shannon Rios – Best Student Conference Paper Finalist Award, the 2015 IEEE/ASME International Conference on Advanced Intelligent Mechatronics.

- Yik Ren Teo – Best Student Conference Paper Finalist, the 2015 IEEE Multi-Conference on Systems and Control (MSC).

- Sachin Wadikhaye – Best Postgraduate Research Poster, the 2012 IEEE Technologies of the Future.

Funding

- 2017: ARC Discovery Project, $296,000 (sole CI).

- 2015: University Strategic Pilot, $3,000 (Sole CI).

- 2013: University Strategic Pilot, $13,668 (Sole CI).

- 2013: ARC DECRA, $375,000 (Sole CI).

- 2012: University Postdoctoral Research Fellowship, $119,075.

- 2011: University Near Miss Grant, $25,000 (Second CI).

- 2010: University Special Project Grant, $18,000 (Sole CI).

- 2007: University Early Career Research Grant, A$15,500 (Sole CI).

Professional Activities

- Associate Editor: IEEE/ASME Transactions on Mechatronics, 2017.

- Associate Editor: Frontiers in Mechanical Engineering, specialty section Mechatronics (Nature Publishing Group), 2015 – present.

- Associate Editor: International Journal of Advanced Robotic Systems, 2012 – present.

- Steering Committee Member: International Conference on Manipulation, Automation and Robotics at Small Scales, Paris, France, 2016.

- Local Arrangement Chair: IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Wollongong, Australia, 2013.

- Organising Committee Member: 2nd Workshop on Dynamics and Control of Micro and Nanoscale Systems, Newcastle, Australia, 2012.

- Invited sessions organizer:

- 2016 (lead organiser): “Design and Control of Precision Mechatronic Systems”, at the International Conference

on Manipulation, Automation and Robotics at Small Scales, Paris, France;

2014 (lead organiser) & 2015 (co-organiser): “Advances in Micro and Nano-Scale Positioning Systems: Design

and Control”, at the IEEE/ASME International Conference on Advanced Intelligent;

2012 (lead organiser): “Control of Micro and Nano Systems”, at the IEEE Conference on Decision and Control,

Maui, Hawaii;

2012 (lead organiser): “Compliant Nanopositioning”, at the IEEE International Conference on Robotics and

Automation, St. Paul, MN, USA.

- 2016 (lead organiser): “Design and Control of Precision Mechatronic Systems”, at the International Conference

- International Program Committee Member for the following conferences:

- IEEE/ASME International Conference on Advanced Intelligent Mechatronics, 2009 – 2013, 2017.

- IEEE Multiconference on Systems and Control, 2015.

- International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale, 2011 – present.

- Asia International Symposium on Mechatronics, 2010.

Research Impact

- 74 Publications, 36 Journal Papers, 38 Conference Papers, 2 Book Chapters.

- 1716 Citations, H-index: 19 (Google Scholar).

- Consulting: 3M Ltd. Pty., Svitzer, PiezoDrive, etc.

Publications

2025

M. G. Ruppert; B. S. Routley; L. R. McCourt; Y. K. Yong; A. J. Fleming

Modulated-Illumination Intermittent-Contact Tip-Enhanced Raman Spectroscopy Journal Article

In: ACS Nano Letters, vol. 25, iss. 14, 2025.

@article{Ruppert2025,

title = {Modulated-Illumination Intermittent-Contact Tip-Enhanced Raman Spectroscopy},

author = {M. G. Ruppert and B. S. Routley and L. R. McCourt and Y. K. Yong and A. J. Fleming},

doi = {https://doi.org/10.1021/acs.nanolett.4c06397},

year = {2025},

date = {2025-03-13},

urldate = {2025-03-13},

journal = {ACS Nano Letters},

volume = {25},

issue = {14},

abstract = {This article presents a proof-of-concept for a new imaging method that combines tip-enhanced Raman spectroscopy with intermittent-contact atomic force microscopy to provide simultaneous nanometer-scale mechanical imaging with chemical contrast. The foremost difference from a standard tip-enhanced Raman microscope is the Raman illumination, which is modulated by the cantilever drive signal so that illumination is only active when the tip is close to the surface. This approach significantly reduces contact forces and thermal damage due to constant illumination while simultaneously reducing background Raman signals. Near-field optical and dynamic cantilever simulations highlight the effect of the imaging parameters on the tip–sample force and the evanescent field enhancement. The experimental images obtained with this new imaging method demonstrate a lateral resolution sufficient to identify single-walled carbon nanotube bundles with a full width at half-maximum of 20 nm.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

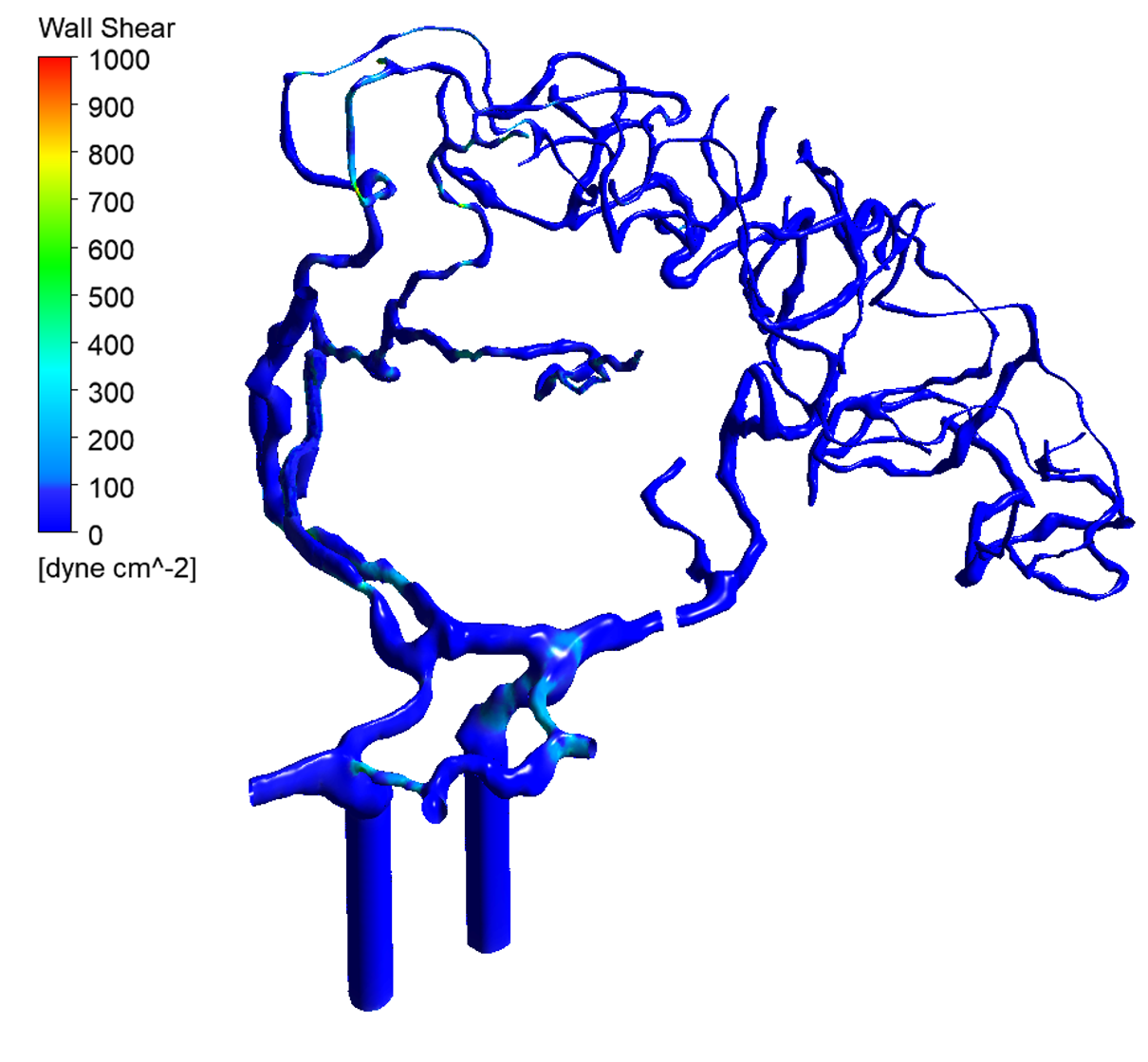

M. Litman; S. Azarpeykan; R. J. Hood; K. Martin; D. Pepperall; D. Omileke; O. Uzun; D. Bhatta; Y. K. Yong; A. Chan; N. Hough; S. Johnson; P. G. Bermejo; F. Miteff; C. G. Esperon; Y. Couch; A. M. Buchan; N. J. Spratt; N. Korin; D. E. Ingber; D. J. Beard

Shear Stress Targeted Delivery of Nitroglycerin to Brain Collaterals Improves Ischaemic Stroke Outcome Working paper

2025.

@workingpaper{nokey,

title = {Shear Stress Targeted Delivery of Nitroglycerin to Brain Collaterals Improves Ischaemic Stroke Outcome},

author = {M. Litman and S. Azarpeykan and R. J. Hood and K. Martin and D. Pepperall and D. Omileke and O. Uzun and D. Bhatta and Y. K. Yong and A. Chan and N. Hough and S. Johnson and P. G. Bermejo and F. Miteff and C. G. Esperon and Y. Couch and A. M. Buchan and N. J. Spratt and N. Korin and D. E. Ingber and D. J. Beard},

url = {https://www.biorxiv.org/content/10.1101/2025.03.25.644833v1.full},

year = {2025},

date = {2025-03-01},

urldate = {2025-04-16},

abstract = {In patients with ischaemic stroke, retrograde perfusion of the penumbra by the leptomeningeal collateral vessels (LMCs) is a strong predictor of clinical outcome, thus raising the possibility that enhancing LMC flow could offer a novel therapeutic approach. Here, using computational modelling we show that LMCs experience elevated fluid shear stress that is significantly higher than that in other blood vessels during ischaemic stroke in animals and humans. We take advantage of this to selectively enhance flow in LMCs using shear-activated nanoparticle aggregates carrying the vasodilator nitroglycerin (NG-NPAs) that specifically release drug in regions of vessels with high shear stress (≥100 dyne/cm2). The NG-NPAs significantly increased LMC-mediated penumbral perfusion, decreased infarct volume, and reduced neurological deficit without altering systemic blood pressure in a rat ischaemic stroke model. The NG-NPAs also did not cause known common side effects of systemic nitrate administration, such as systemic hypotension, cerebral vascular steal, cortical vein dilation, or intracranial pressure elevation. Systemic administration of free NG at the maximal tolerated dose, which was ten times higher than the dose of NG used in the NG-NPAs, did not enhance LMC perfusion and dropped blood pressure. Thus, packaging NG within shear-activated NPAs can potentially enable this widely available vasodilator to become a highly effective therapeutic for ischaemic stroke.},

keywords = {},

pubstate = {published},

tppubtype = {workingpaper}

}

C. J. Carlon; Y. K. Yong; A. J. Fleming

Feasibility of Nano-Acoustic Subsurface Imaging for Atomic Force Microscopy Proceedings Article

In: IEEE International Conference on Mechatronics (ICM), 2025.

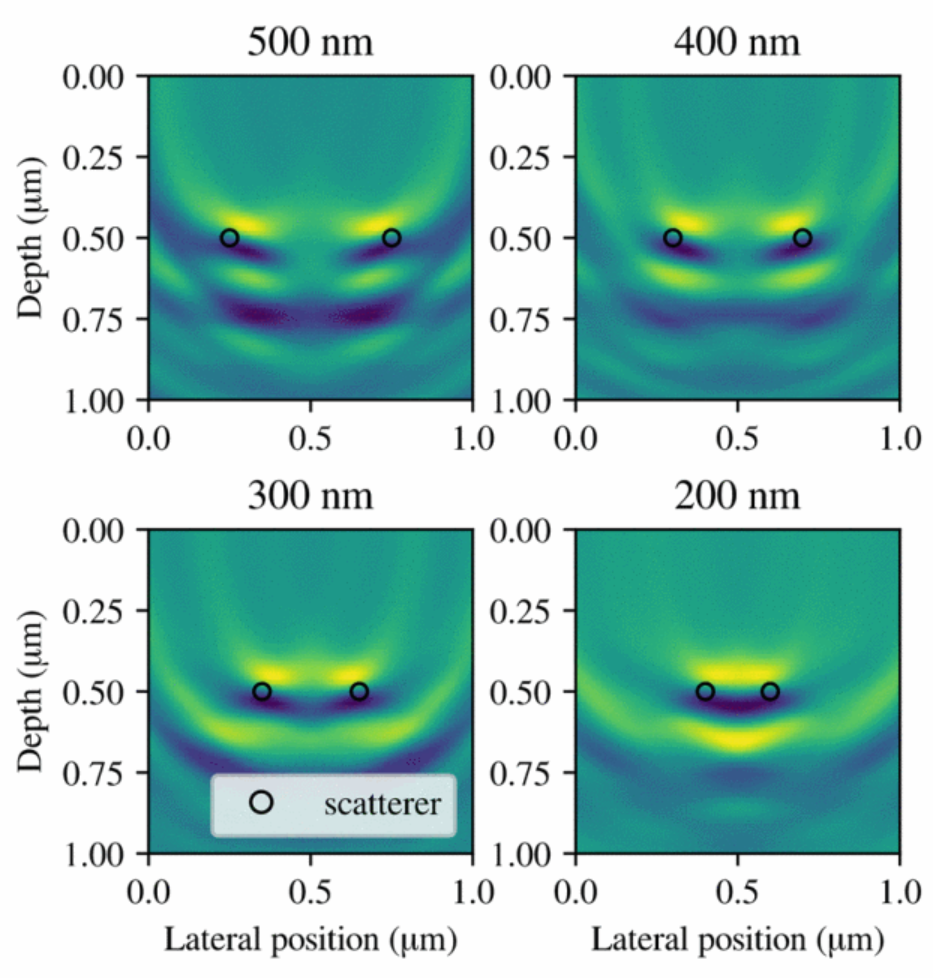

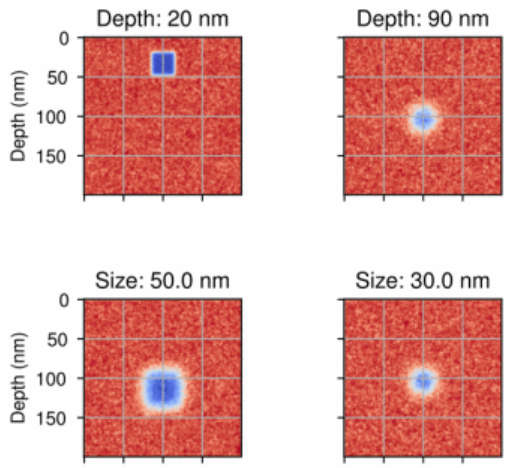

@inproceedings{Carlon2025,

title = {Feasibility of Nano-Acoustic Subsurface Imaging for Atomic Force Microscopy},

author = {C. J. Carlon and Y. K. Yong and A. J. Fleming},

url = {https://ieeexplore-ieee-org.ezproxy.newcastle.edu.au/abstract/document/10934819},

doi = {10.1109/ICM62621.2025.10934819},

year = {2025},

date = {2025-02-28},

booktitle = {IEEE International Conference on Mechatronics (ICM)},

abstract = {The feasibility of a new imaging regime for sub-surface Atomic Force Microscopy (AFM) is investigated using synthetic aperture focusing technique. This technique uses two Atomic Force Microscopy (AFM) probes to emit acoustic pulses and sense echoes. Unlike other existing subsurface AFM methods, Nano-Acoustic Subsurface AFM (NASAFM) provides cross-sectional images of a sample below the surface with depth information in the nanometre scale. In order to determine the best resolution, two ideal wideband AFM probes are considered in simulation. The results show that a 20 ps pulse with a bandwidth of 330 GHz was able to resolve two 50 nm discs, 500 nm below the surface, separated by 340 nm. Future work is needed to understand the relation between resolution and bandwidth, the optimal imaging parameters, and the sensing technique.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

B. J. Stanwell; Y. K. Yong; A. J. Fleming

Feasibility of Nano Electrical Resistive Tomography for Subsurface Atomic Force Microscopy Proceedings Article

In: IEEE International Conference on Mechatronics, 2025.

@inproceedings{Stanwell2025,

title = {Feasibility of Nano Electrical Resistive Tomography for Subsurface Atomic Force Microscopy},

author = {B. J. Stanwell and Y. K. Yong and A. J. Fleming},

url = {https://ieeexplore-ieee-org.ezproxy.newcastle.edu.au/abstract/document/10934851},

doi = {10.1109/ICM62621.2025.10934851},

year = {2025},

date = {2025-02-28},

booktitle = {IEEE International Conference on Mechatronics},

abstract = {This article investigates the feasibility of using a dual-cantilever atomic force microscope for imaging the electrical properties of a sample below the surface. Principles from macro-scale electrical resistive tomography are adapted to utilize measurements from a dual-probe atomic force microscope. A deep-learning method is employed to perform the inversion process and construct the tomography. Simulation results demonstrate that electrical resistive tomography is possible at the nanometre scale but improvements to the inversion algorithms are needed before moving to experimental applications.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

T. R. Young; Y. K. Yong; A. J. Fleming

Data-Driven Inverse Control of Pneumatic Soft Robotic Actuators with On-Off Valves: Simulated Performance Proceedings Article

In: IEEE International Conference on Mechatronics, 2025.

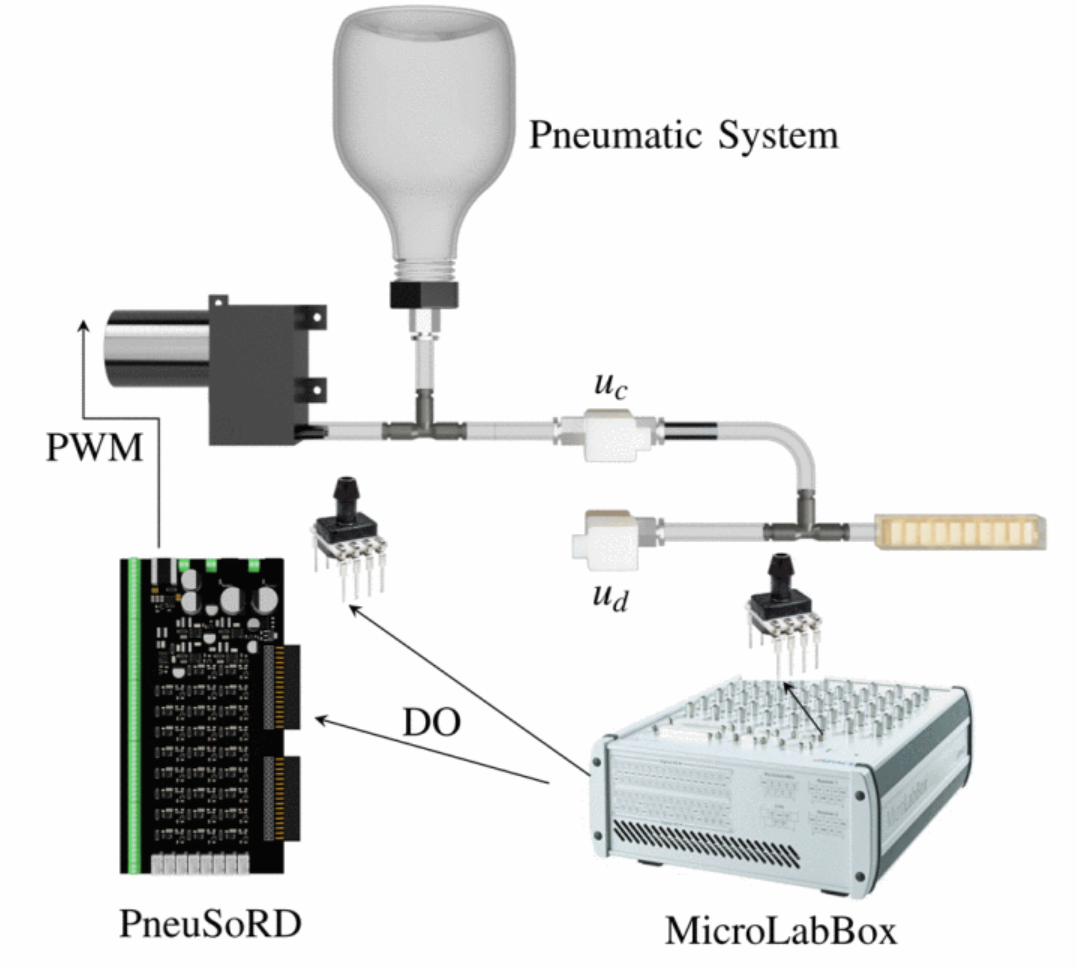

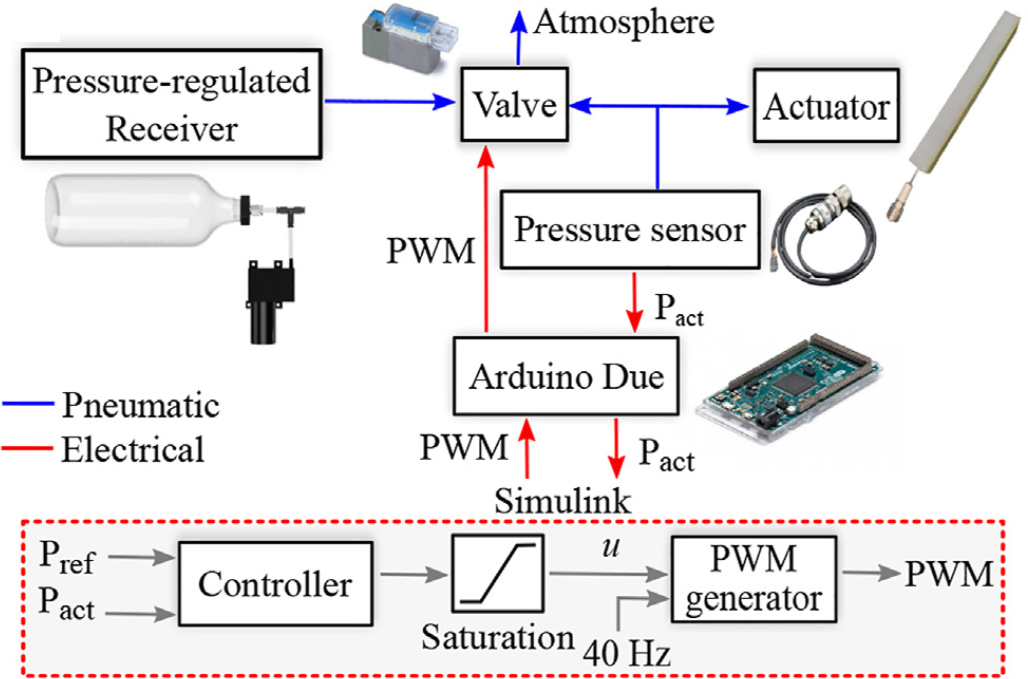

@inproceedings{nokey,

title = {Data-Driven Inverse Control of Pneumatic Soft Robotic Actuators with On-Off Valves: Simulated Performance},

author = {T. R. Young and Y. K. Yong and A. J. Fleming},

url = {https://ieeexplore-ieee-org.ezproxy.newcastle.edu.au/abstract/document/10934841},

doi = {10.1109/ICM62621.2025.10934841},

year = {2025},

date = {2025-02-28},

urldate = {2025-02-28},

booktitle = {IEEE International Conference on Mechatronics},

abstract = {This article describes a data-driven control method for fast and accurate pressure regulation of pneumatic soft robotic actuators with on-off valves. Due to the non-linearity and binary control input, linear controllers are not ideal for pressure regulation as they must be tuned conservatively, which results in a slow transient response. Alternatively, non-linear methods can provide a faster response time but are complicated by the need for an accurate model. This article proposes an inverse control approach, where the control action is parameterized by the valve on-time, and the system output is the cumulative change in pressure after the control action is complete and all system transients have decayed. This approach eliminates the need for a dynamic model and results in a small space of input-output combinations that can be measured from a calibration experiment. The result is a non-linear inverse controller that does not require a dynamic model. The proposed method is compared in simulation to a hysteresis controller with three different valve orifice diameters. Significant improvements to the pressure regulation and valve lifetime are observed. This method is expected to find applications in soft robotics where fast step changes and dynamic trajectories are required.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

2024

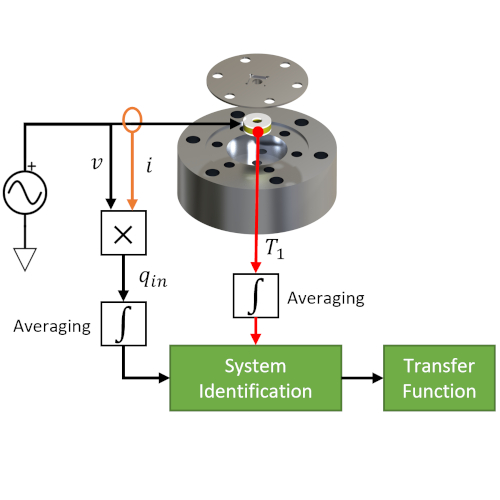

Y. K. Yong; A. A. Eielsen; A. J. Fleming

Thermal Protection of Piezoelectric Actuators Using Complex Electrical Power Measurements and Simplified Thermal Models Journal Article

In: IEEE/ASME Transactions on Mechatronics, vol. 29, iss. 1, 2024, ISBN: 1083-4435.

@article{J24b,

title = {Thermal Protection of Piezoelectric Actuators Using Complex Electrical Power Measurements and Simplified Thermal Models},

author = {Y. K. Yong and A. A. Eielsen and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2024/02/J24b-preprint.pdf},

doi = {10.1109/TMECH.2023.3277437},

isbn = {1083-4435},

year = {2024},

date = {2024-01-01},

urldate = {2024-01-01},

journal = {IEEE/ASME Transactions on Mechatronics},

volume = {29},

issue = {1},

abstract = {This article describes a method for estimating the temperature of high-power piezoelectric actuators when a direct temperature measurement is impractical. The heat flow is estimated from the real component of the electrical power; then, the temperature is estimated by a transfer function that approximates the thermal response of the system. The transfer function can be derived analytically from a lumped-element approximation or calibrated experimentally by using a system identification method. The proposed method is demonstrated on a piezoelectric stack actuator used in a high-speed nanopositioning device. A second-order transfer function estimates the temperature to within 3 ∘ C of a reference measurement for a range of operating conditions. The proposed method is suitable for protecting piezoelectric actuators in applications where direct temperature measurement is impractical, for example, due to space or wiring constraints.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

2023

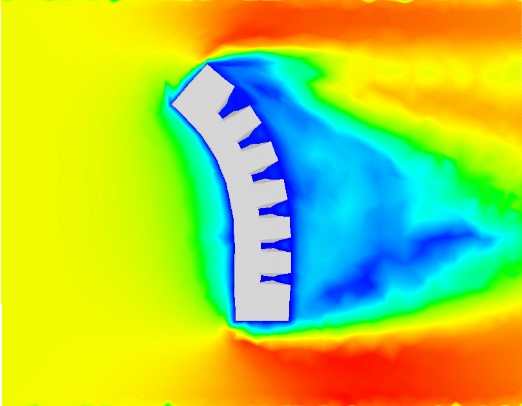

M. S. Xavier; S. Harrison; D. Howard; Y. K. Yong; A. J. Fleming

Modeling of soft fluidic actuators using fluid-structure interaction simulations with underwater applications Journal Article

In: International Journal of Mechanical Sciences, vol. 255, iss. 108437, pp. 1-11, 2023, ISSN: 1879-2162.

@article{J23a,

title = {Modeling of soft fluidic actuators using fluid-structure interaction simulations with underwater applications},

author = {M. S. Xavier and S. Harrison and D. Howard and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2023/06/FSI.pdf},

doi = {10.1016/j.ijmecsci.2023.108437},

issn = {1879-2162},

year = {2023},

date = {2023-05-15},

urldate = {2023-05-15},

journal = {International Journal of Mechanical Sciences},

volume = {255},

issue = {108437},

pages = {1-11},

abstract = {Soft robots have been developed for a variety of applications including gripping, locomotion, wearables and medical devices. For the majority of soft robots, actuation is performed using pneumatics or hydraulics. Many previous works have addressed the modeling of these fluid-driven soft robots using static finite element simulations where the pressure inside the actuator is assumed to be constant and uniform. The assumption of constant internal pressure is a useful simplification but introduces significant errors during events such as pressurization, depressurization, and transient loads from a liquid environment. Applications that use soft actuators for locomotion or propulsion operate using a sequence of transient events, so accurate simulation of these events is critical to optimizing performance. To improve the simulation of soft fluidic actuators and enable the modeling of both internal and external fluid flow in underwater applications, this work describes a fully-coupled, three-dimensional fluid–structure interaction simulation approach, where the pressure and flow dynamics are explicitly solved. This approach provides a realistic simulation of soft actuators in fluid environments, and permits the optimization of transient responses, which may be due to a combination of environmental fluid loads and non-uniform pressurization. The proposed methods are demonstrated in a number of case studies and experiments for a range of actuation and both internal and external inlet flow configurations, including bending actuators, a soft robotic fish fin for propulsion, and experimental results of a bending actuator in a high-speed fluid, which correlate closely with simulations. The proposed approach is expected to assist in the design, modeling, and optimization of bioinspired soft robots in underwater applications.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

2022

M. S. Xavier; C. D. Tawk; A. Zolfagharian; J. Pinskier; D. Howard; T. Young; J. Lai; S. Harrison; Y. K. Yong; M. Bodaghi; A. J. Fleming

Soft Pneumatic Actuators: A Review of Design, Fabrication, Modeling, Sensing, Control and Applications Journal Article

In: IEEE Access, vol. 10, pp. 59442-59485, 2022, ISSN: 2169-3536.

@article{J22h,

title = {Soft Pneumatic Actuators: A Review of Design, Fabrication, Modeling, Sensing, Control and Applications},

author = {M. S. Xavier and C. D. Tawk and A. Zolfagharian and J. Pinskier and D. Howard and T. Young and J. Lai and S. Harrison and Y. K. Yong and M. Bodaghi and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2023/02/J22h-1.pdf},

doi = {10.1109/ACCESS.2022.3179589},

issn = {2169-3536},

year = {2022},

date = {2022-06-02},

urldate = {2022-06-02},

journal = {IEEE Access},

volume = {10},

pages = {59442-59485},

abstract = {Soft robotics is a rapidly evolving field where robots are fabricated using highly deformable materials and usually follow a bioinspired design. Their high dexterity and safety makes them ideal for applications such as gripping, locomotion, and biomedical devices, where the environment is highly dynamic and sensitive to physical interaction. Pneumatic actuation remains the dominant technology in soft robotics due to its low cost and mass, fast response time, and easy implementation. Given the significant number of publications in soft robotics over recent years, newcomers and even established researchers may have difficulty assessing the state of the art. To address this issue, this article summarizes the development of soft pneumatic actuators and robots up until the date of publication. The scope of this article includes the design, modeling, fabrication, actuation, characterization, sensing, control, and applications of soft robotic devices. In addition to a historical overview, there is a special emphasis on recent advances such as novel designs, differential simulators, analytical and numerical modeling methods, topology optimization, data-driven modeling and control methods, hardware control boards, and nonlinear estimation and control techniques. Finally, the capabilities and limitations of soft pneumatic actuators and robots are discussed and directions for future research are identified.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

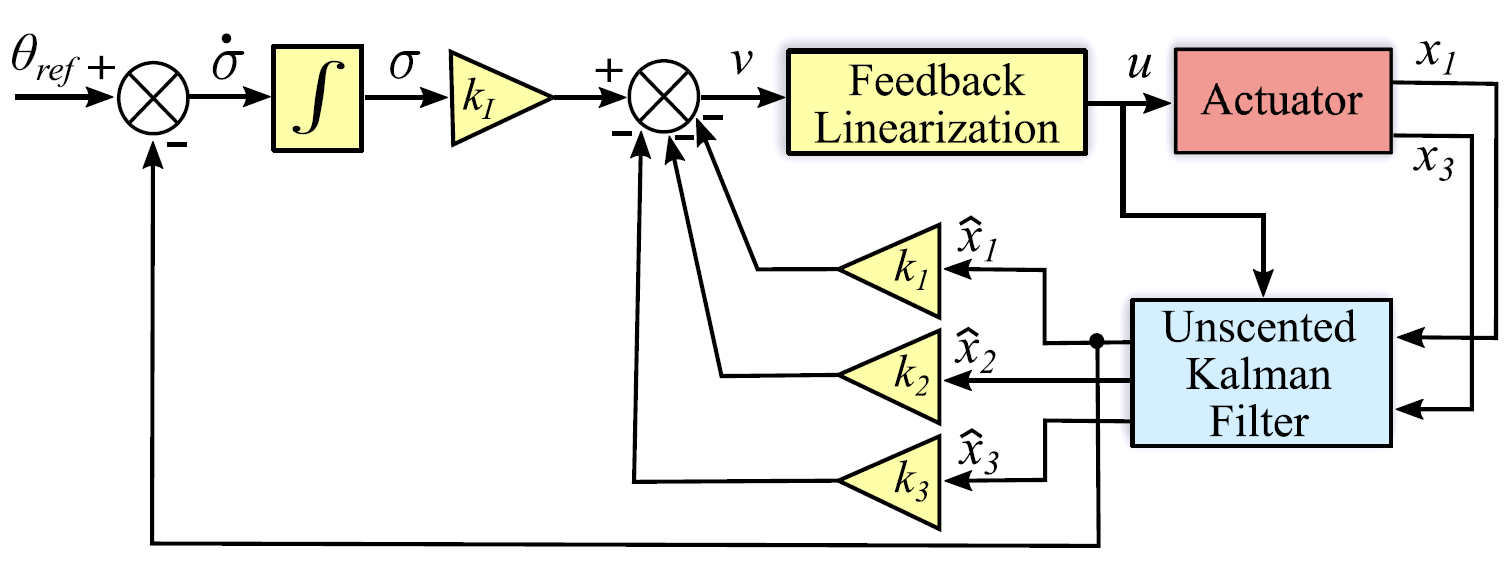

M. S. Xavier; A. J. Fleming; Y. K. Yong

Nonlinear Estimation and Control of Bending Soft Pneumatic Actuators Using Feedback Linearization and UKF Journal Article

In: IEEE/ASME Transactions on Mechatronics, vol. 27, iss. 4, pp. 1919-1927, 2022, ISSN: 1083-4435.

@article{J22e,

title = {Nonlinear Estimation and Control of Bending Soft Pneumatic Actuators Using Feedback Linearization and UKF },

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2023/02/J22e-1.pdf},

doi = {10.1109/TMECH.2022.3155790},

issn = {1083-4435},

year = {2022},

date = {2022-06-01},

urldate = {2022-06-01},

journal = {IEEE/ASME Transactions on Mechatronics},

volume = {27},

issue = {4},

pages = {1919-1927},

abstract = {In this article, we combine nonlinear estimation and control methods for precise bending angle control in soft pneumatic actuators driven by a pressure source and single low-cost ON/OFF solenoid valve. First, a complete model for the soft actuator is derived, which includes both the motion and pressure dynamics. An unscented Kalman filter (UKF) is used to estimate the velocity state and filter noisy measurements from a pressure sensor and an embedded resistive flex sensor. Then, a feedback linearization approach is used with pole placement and linear quadratic regulator (LQR) controllers for bending angle control. To compensate for model uncertainties and improve reference tracking, integral action is incorporated to both controllers. The closed-loop performance of the nonlinear estimation and control approach is experimentally evaluated with a soft pneumatic network actuator. The simulation and experimental results show that the UKF provides accurate state estimation from noisy sensor measurements. The results demonstrate the effectiveness and robustness of the proposed observer-based nonlinear controllers for bending angle trajectory tracking.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

Linlin Li; A. J. Fleming; Y. K. Yong; S. S. Aphale; LiMin Zhu

High Performance Raster Scanning of Atomic Force Microscopy Using Model-free Repetitive Control Journal Article

In: Mechanical Systems and Signal Processing, vol. 173, no. 109027, 2022, ISSN: 0888-3270.

@article{J22f,

title = {High Performance Raster Scanning of Atomic Force Microscopy Using Model-free Repetitive Control},

author = {Linlin Li and A. J. Fleming and Y. K. Yong and S. S. Aphale and LiMin Zhu},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/08/J22f.pdf},

doi = {10.1016/j.ymssp.2022.109027},

issn = {0888-3270},

year = {2022},

date = {2022-05-01},

urldate = {2022-05-01},

journal = {Mechanical Systems and Signal Processing},

volume = {173},

number = {109027},

abstract = {The image quality of an atomic force microscope depends on the tracking performance of the lateral X and Y axis positioner. To reduce the requirement for accurate system models, this article describes a method based on Model free Repetitive Control (MFRC) for high performance control of fast triangular trajectories in the X-axis, and a slow staircase trajectory in the Y-axis, while simultaneously achieving coupling compensation from the X-axis to Y-axis. The design and stability analysis of the MFRC scheme are presented in detail. The tracking results are experimen tally evaluated with a range of different load conditions, showing the efficacy of the method with large variations in plant dynamics. To address the coupling from the X-axis to the Y-axis while tracking the non-periodic staircase trajectories, a pre-learning step is used to generate the compensation signals, which is combined in a feedforward manner in real-time implementations. This approach is also applied to address the problem of longer convergence if needed. Experimental tracking control and coupling compensation is demonstrated on a commercially available piezoelectric-actuated scanner. The proposed method reduces the root-mean-square tracking from 191.4 nm in open loop or 194.6 nm with PI control, to 2.8 nm with PI+MFRC control at 100 Hz scan rate, which demonstrates the significant improvement achieved by the proposed method.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

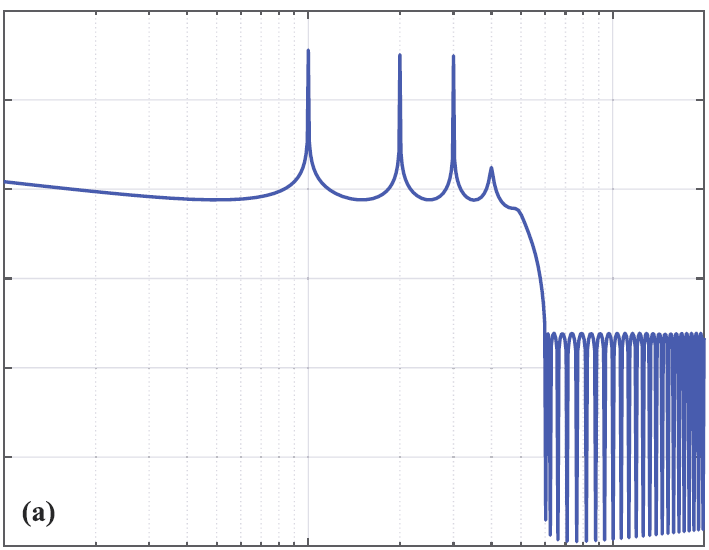

M. S. Xavier; A. J. Fleming; Y. K. Yong

Model-Based Nonlinear Feedback Controllers for Pressure Control of Soft Pneumatic Actuators Using On/Off Valves Journal Article

In: Frontiers in Robotics and AI, vol. 9, 2022, ISSN: 2296-9144.

@article{J22d,

title = {Model-Based Nonlinear Feedback Controllers for Pressure Control of Soft Pneumatic Actuators Using On/Off Valves},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J22d.pdf},

doi = {10.3389/frobt.2022.818187},

issn = {2296-9144},

year = {2022},

date = {2022-03-17},

urldate = {2022-03-17},

journal = {Frontiers in Robotics and AI},

volume = {9},

abstract = {This article describes the application and comparison of three nonlinear feedback controllers for low-level control of soft actuators driven by a pressure source and single high-speed on/off solenoid valve. First, a mathematical model of the pneumatic system is established and the limitations of the open-loop system are evaluated. Next, a model of the pneumatic system is developed using Simscape Fluids to evaluate the performance of various control strategies. In this article, State-Dependent Riccati Equation control, sliding mode control, and feedback linearization are considered. To improve robustness to model uncertainties, the sliding mode and feedback linearization control strategies are augmented with integral action. The model of the pneumatic system is also used to develop a feedforward component, which is added to a PI controller with anti-windup. The simulation and experimental results demonstrate the effectiveness of the proposed controllers for pressure tracking.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

N. F. S. de Bem; M. G. Ruppert; A. J. Fleming; Y. K. Yong

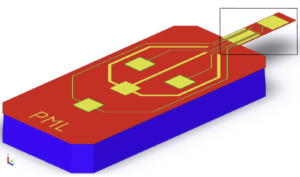

In: Sensors and Actuators A: Physical, vol. 338, pp. 113496, 2022, ISSN: 0924-4247, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@article{J22a,

title = {Simultaneous tip force and displacement sensing for AFM cantilevers with on-chip actuation: Design and characterization for off-resonance tapping mode},

author = {N. F. S. de Bem and M. G. Ruppert and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J22a.pdf},

doi = {10.1016/j.sna.2022.113496},

issn = {0924-4247},

year = {2022},

date = {2022-03-08},

urldate = {2022-03-08},

journal = {Sensors and Actuators A: Physical},

volume = {338},

pages = {113496},

abstract = {The use of integrated on-chip actuation simplifies the identification of a cantilever resonance, can improve imaging speed, and enables the use of smaller cantilevers, which is required for low-force imaging at high speed. This article describes a cantilever with on-chip actuation and novel dual-sensing capabilities for AFM. The dual-sensing configuration allows for tip displacement and tip force to be measured simultaneously. A mathematical model is developed and validated with finite element analysis. A physical prototype is presented, and its calibration and validation are presented. The cantilever is optimized for use in off-resonance tapping modes. Experimental results demonstrate an agreement between the on-chip sensors and external force and displacement measurements.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

M. G. Ruppert; D. Martin-Jimenez; Y. K. Yong; A. Ihle; A. Schirmeisen; A. J. Fleming; D. Ebeling

Experimental Analysis of Tip Vibrations at Higher Eigenmodes of QPlus Sensors for Atomic Force Microscopy Journal Article

In: Nanotechnology, vol. 33, iss. 18, pp. 185503, 2022, ISSN: 1361-6528, (This work was supported in part by the Australian Research Council Discovery Project DP170101813).

@article{Ruppert2022,

title = {Experimental Analysis of Tip Vibrations at Higher Eigenmodes of QPlus Sensors for Atomic Force Microscopy},

author = {M. G. Ruppert and D. Martin-Jimenez and Y. K. Yong and A. Ihle and A. Schirmeisen and A. J. Fleming and D. Ebeling},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J22c.pdf},

doi = {10.1088/1361-6528/ac4759},

issn = {1361-6528},

year = {2022},

date = {2022-02-10},

urldate = {2022-02-10},

journal = {Nanotechnology},

volume = {33},

issue = {18},

pages = {185503},

abstract = {QPlus sensors are non-contact atomic force microscope probes constructed from a quartz tuning fork and a tungsten wire with an electrochemically etched tip. These probes are self-sensing and offer an atomic-scale spatial resolution. Therefore, qPlus sensors are routinely used to visualize the chemical structure of adsorbed organic molecules via the so-called bond imaging technique. This is achieved by functionalizing the AFM tip with a single CO molecule and exciting the sensor at the first vertical cantilever resonance mode. Recent work using higher-order resonance modes has also resolved the chemical structure of single organic molecules. However, in these experiments, the image contrast can differ significantly from the conventional bond imaging contrast, which was suspected to be caused by unknown vibrations of the tip. This work investigates the source of these artefacts by using a combination of mechanical simulation and laser vibrometry to characterize a range of sensors with different tip wire geometries. The results show that increased tip mass and length cause increased torsional rotation of the tuning fork beam due to the off-center mounting of the tip wire, and increased flexural vibration of the tip. These undesirable motions cause lateral deflection of the probe tip as it approaches the sample, which is rationalized to be the cause of the different image contrast. The results also provide a guide for future probe development to reduce these issues.},

note = {This work was supported in part by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

2021

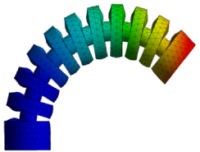

M. S. Xavier; C. D. Tawk; Y. K. Yong; A. J. Fleming

3D-printed omnidirectional soft pneumatic actuators: Design, modeling and characterization Journal Article

In: Sensors and Actuators: A. Physical , vol. 332, iss. 2, pp. 113199, 2021, ISSN: 0924-4247.

@article{Xavier2021,

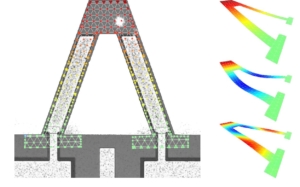

title = {3D-printed omnidirectional soft pneumatic actuators: Design, modeling and characterization},

author = {M. S. Xavier and C. D. Tawk and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J21f.pdf},

doi = {10.1016/j.sna.2021.113199},

issn = {0924-4247},

year = {2021},

date = {2021-12-25},

urldate = {2021-12-25},

journal = {Sensors and Actuators: A. Physical },

volume = {332},

issue = {2},

pages = {113199},

abstract = {Soft pneumatic actuators are usually fabricated using molding and casting techniques with silicone rubbers, which requires intensive manual labor and limits repeatability and design flexibility for complex geometries. This article presents the design and direct 3D-printing of novel omnidirectional soft pneumatic actuators using stereolithography (SLA) with an elastic resin and fused deposition modeling (FDM) with a thermoplastic polyurethane (TPU). The actuator is modeled and optimized for bending performance using the finite element method along with a hyperelastic material model that is based on experimental uniaxial tensile data. The designs inspired by fast pneumatic network actuators (PneuNets) allow for multimodal actuation including bending, extension and contraction motions under positive, negative or differential pressures. The predicted results from the finite element method are compared with the experimental results for a range of actuation configurations. These novel omnidirectional actuators have significant potential in applications such as pipe inspection and biomedical devices.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

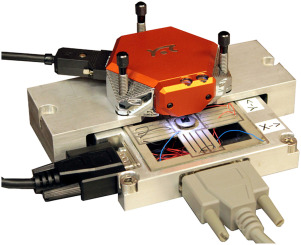

T. R. Young; M. S. Xavier; Y. K. Yong; A. J. Fleming

A Control and Drive System for Pneumatic Soft Robots: PneuSoRD Proceedings Article

In: International Conference on Intelligent Robots and Systems, Prague, Czech Republic , 2021, ISSN: 2153-0866.

@inproceedings{Young2021,

title = {A Control and Drive System for Pneumatic Soft Robots: PneuSoRD},

author = {T. R. Young and M. S. Xavier and Y. K. Yong and A. J. Fleming },

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/C21b.pdf},

doi = {10.1109/IROS51168.2021.9635874},

issn = {2153-0866},

year = {2021},

date = {2021-09-27},

urldate = {2021-09-27},

booktitle = {International Conference on Intelligent Robots and Systems},

address = {Prague, Czech Republic },

abstract = {This article describes an open-source hardware platform for controlling pneumatic soft robotic systems and presents the comparison of control schemes with on-off and proportional valves. The Pneumatic Soft Robotics Driver (PneuSoRD) can be used with up to one pump and pressure accumulator, 26 on-off valves, and 5 proportional valves, any of which can be operated in open or closed-loop control using up to 12 sensor inputs, which allows for the simultaneous control of a large number of soft actuators. The electronic driver connects to a National Instruments myRIO controller or an Arduino Due with the use of an adapter shield. A library of pressure control algorithms in both LabVIEW and Simulink is provided that includes bang-bang control, hysteresis control and PID control using on-off or proportional valves. LabVIEW and Simulink provide user-friendly interfaces for rapid prototyping of control algorithms and real-time evaluation of pressure dynamics. The characteristics and performance of these control methods and pneumatic setups are evaluated to simplify the choice of valves and control algorithm for a given application. },

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

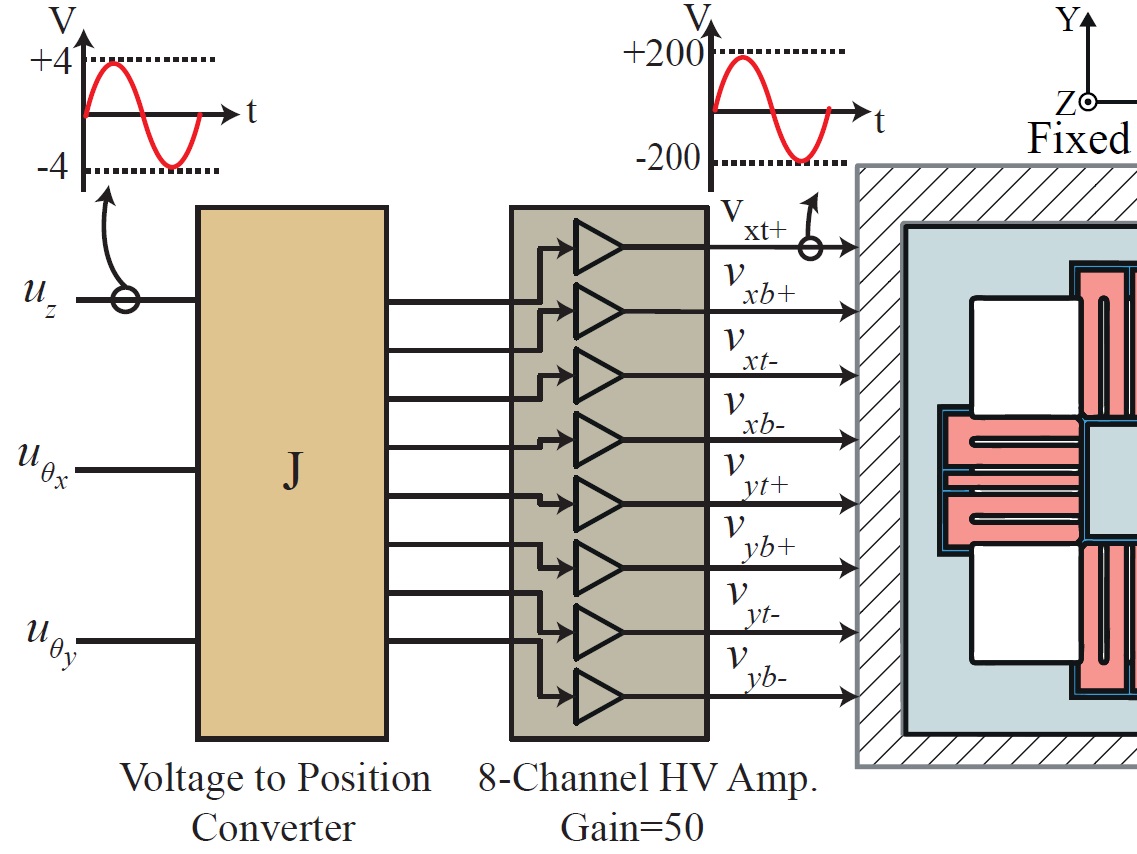

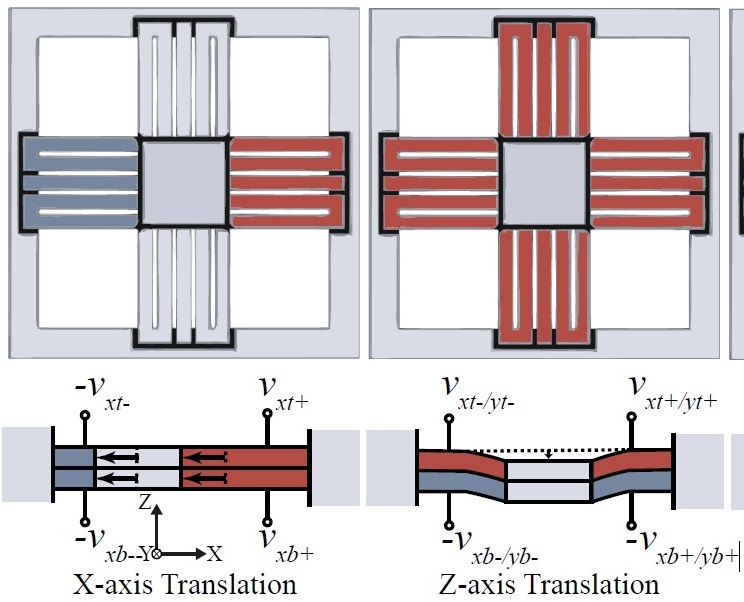

M. Omidbeike; S. I. Moore; Y. K. Yong; A. J. Fleming

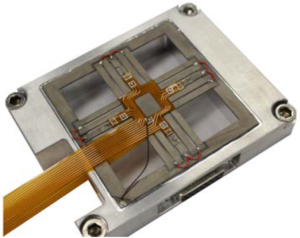

Five-Axis Bimorph Monolithic Nanopositioning Stage: Design, Modeling, and Characterization Journal Article

In: Sensors and Actuators A: Physical, vol. 332, iss. 1, 2021, ISSN: 0924-4247.

@article{Omidbeike2021,

title = {Five-Axis Bimorph Monolithic Nanopositioning Stage: Design, Modeling, and Characterization},

author = {M. Omidbeike and S. I. Moore and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J21g.pdf},

doi = {10.1016/j.sna.2021.113125},

issn = {0924-4247},

year = {2021},

date = {2021-09-16},

urldate = {2021-09-16},

journal = {Sensors and Actuators A: Physical},

volume = {332},

issue = {1},

abstract = {The article describes the design and modeling of a five-axis monolithic nanopositioning stage constructed from a bimorph piezoelectric sheet. Six-axis motion is also possible but requires 16 amplifier channels rather than 8. The nanopositioner is ultra low profile with a thickness of 1 mm. Analytical modeling and finite-element-analysis accurately predict the experimental performance. The stage was conservatively driven with 33% of the maximum voltage, which resulted in an X and Y travel range of 6.22 μm and 5.27 μm respectively; a Z travel range of 26.5 μm; and a rotational motion of 600 μrad and 884 μrad about the X and Y axis respectively. The first resonance frequency occurs at 883 Hz in the Z axis. Experimental atomic force microscopy is performed using the proposed device as a sample scanner.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

M. G. Ruppert; N. F. S. de Bem; A. J. Fleming; Y. K. Yong

Characterization of Active Microcantilevers Using Laser Doppler Vibrometry Book Chapter

In: Vibration Engineering for a Sustainable Future , Chapter 45, Springer, 2021, ISBN: 978-3-030-48153-7, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@inbook{Ruppert2021b,

title = {Characterization of Active Microcantilevers Using Laser Doppler Vibrometry},

author = {M. G. Ruppert and N. F. S. de Bem and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/BC21a.pdf},

doi = {10.1007/978-3-030-48153-7},

isbn = {978-3-030-48153-7},

year = {2021},

date = {2021-06-18},

urldate = {2021-06-18},

booktitle = {Vibration Engineering for a Sustainable Future

},

issuetitle = {Experiments, Materials and Signal Processing, Vol. 2},

publisher = {Springer},

chapter = {45},

abstract = {Active atomic force microscope cantilevers with on-chip actuation and sensing provide several advantages over passive cantilevers which rely on piezoacoustic base-excitation and the optical beam deflection measurement. Most importantly, these cantilevers provide clean frequency responses, the possibility of down-scaling and parallelization to cantilever arrays as well as the absence of optical interferences. In this paper, we demonstrate the analysis and calibration steps for three active cantilever geometries with integrated piezoelectric actuation. For this purpose, laser Doppler vibrometry (LDV) is used to experimentally obtain the deflection mode shapes of the first three eigenmodes, calibrate actuation gains, and to determine the dynamic modal stiffnesses using the Brownian spectrum of the cantilever. The experimental values are compared with finite element simulations.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {inbook}

}

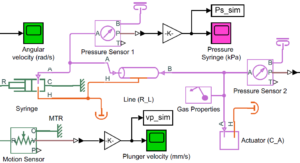

M. S. Xavier; A. J. Fleming; Y. K. Yong

Design and Control of Pneumatic Systems for Soft Robotics: a Simulation Approach Journal Article

In: IEEE Robotics and Automation Letters, vol. 6, iss. 3, pp. 5800-5807, 2021, ISSN: 2377-3766.

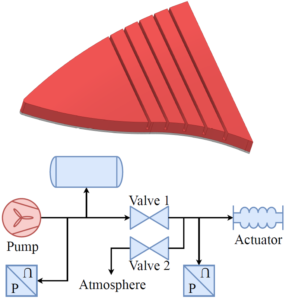

@article{J21d,

title = {Design and Control of Pneumatic Systems for Soft Robotics: a Simulation Approach},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/J21d.pdf},

doi = {10.1109/LRA.2021.3086425},

issn = {2377-3766},

year = {2021},

date = {2021-06-04},

urldate = {2021-06-04},

journal = {IEEE Robotics and Automation Letters},

volume = {6},

issue = {3},

pages = {5800-5807},

abstract = {Pressure control plays a major role in the overall performance of fluid-driven soft robots. Due to the increasing demand for higher speed actuation and precision, a need exists for a practical design methodology that converts actuator performance specifications to a set of minimum pneumatic specifications, such as receiver volume and pressure, and valve conductance. This article presents a systematic parameter selection approach for pneumatic soft robotic systems by taking into consideration the desired closed-loop pressure responses. The two controllers under evaluation here are the PI controller with anti-windup and the on-off controller with hysteresis. Simulations are developed within Simscape Fluids to evaluate the effect of physical components and controller parameters on the actuator performance. The proposed parameter selection procedures are then applied on three soft actuators and their closed-loop pressure responses are experimentally evaluated. The measured pressure responses are in close agreement with the simulations and satisfy the rise time specifications.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

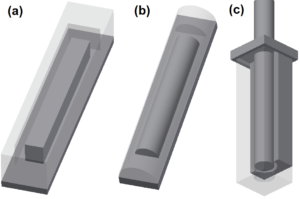

S. I. Moore; Y. K. Yong; M. Omidbeike; A. J. Fleming

Serial-kinematic monolithic nanopositioner with in-plane bender actuators Journal Article

In: Mechatronics, vol. 75, no. 102541, 2021, ISBN: 0957-4158.

@article{Moore2021,

title = {Serial-kinematic monolithic nanopositioner with in-plane bender actuators},

author = {S. I. Moore and Y. K. Yong and M. Omidbeike and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/03/J21c.pdf},

doi = {https://doi.org/10.1016/j.mechatronics.2021.102541},

isbn = {0957-4158},

year = {2021},

date = {2021-03-23},

journal = {Mechatronics},

volume = {75},

number = {102541},

abstract = {This article describes a monolithic nanopositioner constructed from in-plane bending actuators which provide greater deflection than previously reported extension actuators, at the expense of stiffness and resonance frequency. The proposed actuators are demonstrated by constructing an XY nanopositioning stage with a serial kinematic design. Analytical modeling and finite-element-analysis accurately predicts the experimental performance of the nanopositioner. A 10μm range is achieved in the X and Y axes with an applied voltage of +/-200 V. The first resonance mode occurs at 250 Hz in the Z axis. The stage is demonstrated for atomic force microscopy imaging.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

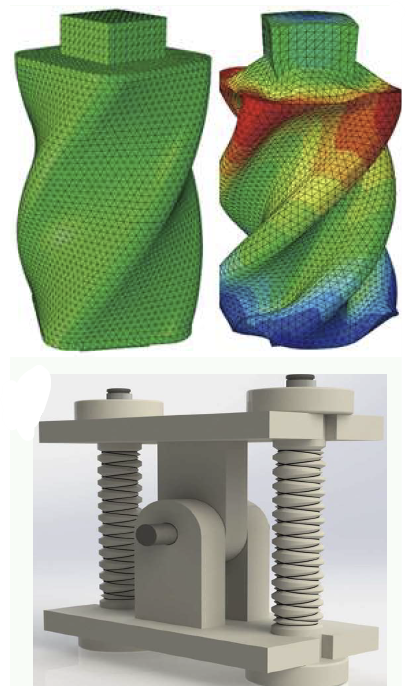

M. S. Xavier; A. J. Fleming; Y. K. Yong

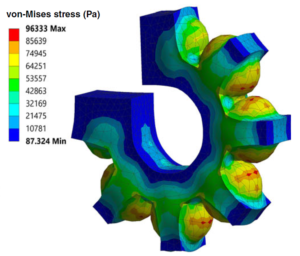

Finite Element Modeling of Soft Fluidic Actuators: Overview and Recent Developments Journal Article

In: Advanced Intelligent Systems, vol. 3, no. 2, pp. 2000187, 2021, ISBN: 2640-4567.

@article{J21b,

title = {Finite Element Modeling of Soft Fluidic Actuators: Overview and Recent Developments},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/02/J21b.pdf},

doi = {10.1002/aisy.202000187},

isbn = {2640-4567},

year = {2021},

date = {2021-02-01},

journal = {Advanced Intelligent Systems},

volume = {3},

number = {2},

pages = {2000187},

abstract = {Many soft robots are composed of soft fluidic actuators that are fabricated from silicone rubbers and use hydraulic or pneumatic actuation. The strong nonlinearities and complex geometries of soft actuators hinder the development of analytical models to describe their motion. Finite element modeling provides an effective solution to this issue and allows the user to predict performance and optimize soft actuator designs. Herein, the literature on a finite element analysis of soft actuators is reviewed. First, the required nonlinear elasticity concepts are introduced with a focus on the relevant models for soft robotics. In particular, the procedure for determining material constants for the hyperelastic models from material testing and curve fitting is explored. Then, a comprehensive review of constitutive model parameters for the most widely used silicone rubbers in the literature is provided. An overview of the procedure is provided for three commercially available software packages (Abaqus, Ansys, and COMSOL). The combination of modeling procedures, material properties, and design guidelines presented in this article can be used as a starting point for soft robotic actuator design.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

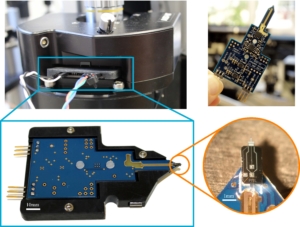

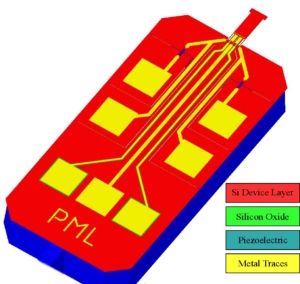

M. G. Ruppert; A. J. Fleming; Y. K. Yong

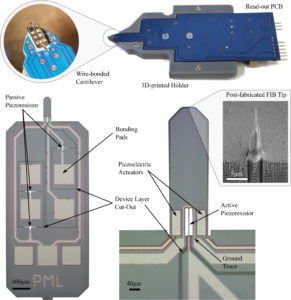

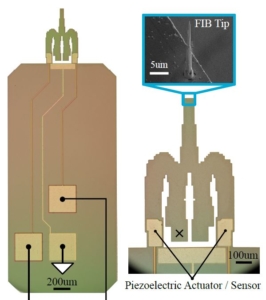

Active atomic force microscope cantilevers with integrated device layer piezoresistive sensors Journal Article

In: Sensors & Actuators: A. Physical, vol. 319, pp. 112519, 2021, ISSN: 0924-4247, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@article{Ruppert2021,

title = {Active atomic force microscope cantilevers with integrated device layer piezoresistive sensors},

author = {M. G. Ruppert and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/01/J21a.pdf},

doi = {10.1016/j.sna.2020.112519},

issn = {0924-4247},

year = {2021},

date = {2021-01-19},

urldate = {2021-01-19},

journal = {Sensors & Actuators: A. Physical},

volume = {319},

pages = {112519},

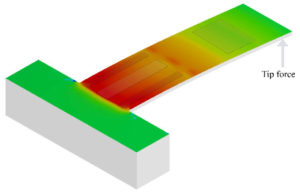

abstract = {Active atomic force microscope cantilevers with on-chip actuation and sensing provide several advantages over

passive cantilevers which rely on piezoacoustic base-excitation and optical beam deflection measurement. Active

microcantilevers exhibit a clean frequency response, provide a path-way to miniturization and parallelization and

avoid the need for optical alignment. However, active microcantilevers are presently limited by the feedthrough

between actuators and sensors, and by the cost associated with custom microfabrication. In this work, we propose

a hybrid cantilever design with integrated piezoelectric actuators and a piezoresistive sensor fabricated from the

silicon device layer without requiring an additional doping step. As a result, the design can be fabricated using a

commercial five-mask microelectromechanical systems fabrication process. The theoretical piezoresistor sensitivity

is compared with finite element simulations and experimental results obtained from a prototype device. The

proposed approach is demonstrated to be a promising alternative to conventional microcantilever actuation and

deflection sensing},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

passive cantilevers which rely on piezoacoustic base-excitation and optical beam deflection measurement. Active

microcantilevers exhibit a clean frequency response, provide a path-way to miniturization and parallelization and

avoid the need for optical alignment. However, active microcantilevers are presently limited by the feedthrough

between actuators and sensors, and by the cost associated with custom microfabrication. In this work, we propose

a hybrid cantilever design with integrated piezoelectric actuators and a piezoresistive sensor fabricated from the

silicon device layer without requiring an additional doping step. As a result, the design can be fabricated using a

commercial five-mask microelectromechanical systems fabrication process. The theoretical piezoresistor sensitivity

is compared with finite element simulations and experimental results obtained from a prototype device. The

proposed approach is demonstrated to be a promising alternative to conventional microcantilever actuation and

deflection sensing

2020

N. F. S. de Bem; M. G. Ruppert; Y. K. Yong; A. J. Fleming

Integrated force and displacement sensing in active microcantilevers for off-resonance tapping mode atomic force microscopy Proceedings Article

In: International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), pp. 1-6, 2020, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@inproceedings{C20c,

title = {Integrated force and displacement sensing in active microcantilevers for off-resonance tapping mode atomic force microscopy},

author = {N. F. S. de Bem and M. G. Ruppert and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/01/C20c.pdf},

doi = {10.1109/MARSS49294.2020.9307881},

year = {2020},

date = {2020-11-30},

urldate = {2020-11-30},

booktitle = {International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS)},

pages = {1-6},

abstract = {Integrated on-chip actuation and sensing in microcantilevers for atomic force microscopy (AFM) allows faster scanning speeds, cleaner frequency responses and smaller cantilevers. However, a single integrated sensor suffers from crosscoupling between displacements originating from tip-sample forces and direct actuation. This paper addresses this issue by presenting a novel microcantilever with on-chip actuation and integrated dual sensing for AFM with application to offresonance tapping modes in AFM. The proposed system is able to measure tip force and deflection simultaneously. A mathematical model is developed for a rectangular cantilever to describe the system and is validated with finite element analysis.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

M. Omidbeike; Y. K. Yong; A. J. Fleming

Sensing and Decentralized Control of a Five-Axis Monolithic Nanopositioning Stage Proceedings Article

In: IFAC World Congress, pp. 9087-9092, 2020, ISSN: 9087-9092.

@inproceedings{C20a,

title = {Sensing and Decentralized Control of a Five-Axis Monolithic Nanopositioning Stage},

author = {M. Omidbeike and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2022/03/C20a.pdf},

doi = {10.1016/j.ifacol.2020.12.2141},

issn = {9087-9092},

year = {2020},

date = {2020-07-11},

urldate = {2020-07-11},

booktitle = {IFAC World Congress},

volume = {53},

number = {2},

pages = {9087-9092},

abstract = {This article describes the design and calibration of a five degree-of-freedom linearand angular displacement sensor utilizing piezoresistive strain gages. A simple decentralized controller is then implemented to follow linear and angular reference signals. The foremost difficulty with piezoresistive sensors is their high-temperature sensitivity. In addition, they are sensitive to motion in multiple degrees of freedom, which must be decoupled before use as a displacement sensor. A new sensing design is proposed which provides decoupled measurements of linear and angular displacements in multi-axis monolithic nanopositioning stages. The proposed method employs system identification and feedforward techniques to calibrate each axis and minimize cross-coupling. },

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

M. S. Xavier; A. J. Fleming; Y. K. Yong

Modelling and Simulation of Pneumatic Sources for Soft Robotic Applications Proceedings Article

In: IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Boston, MA, 2020.

@inproceedings{C20b,

title = {Modelling and Simulation of Pneumatic Sources for Soft Robotic Applications},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/09/AIM2020_Published.pdf},

doi = {10.1109/aim43001.2020.9158802},

year = {2020},

date = {2020-07-01},

booktitle = {IEEE/ASME International Conference on Advanced Intelligent Mechatronics},

address = {Boston, MA},

abstract = {The mathematical models for two widely used pneumatic systems in the soft robotics community are presented: syringe pumps and compressed air systems. These models enable prediction and optimisation of performance of soft actuators under pressurisation, allowing the user to select pneumatic components for a desired behaviour. Analytical models are confirmed with simulations developed using SimScape Fluids and SimScape Electrical within Simulink/MATLAB. By using a polytropic law, the models show agreement with the simulations with less than 10% discrepancy for the typical pressures used with soft actuators. Syringe pumps are shown to be much slower compared to the compressed air systems. In the latter, the addition of an air receiver allows very short actuation time.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

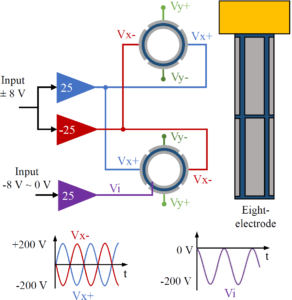

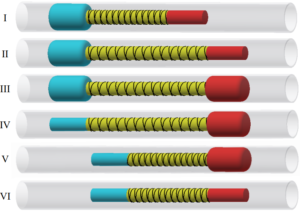

D. S. Raghunvanshi; S. I. Moore; A. J. Fleming; Y. K. Yong

Electrode Configurations for Piezoelectric Tube Actuators With Improved Scan Range and Reduced Cross-Coupling Journal Article

In: IEEE/ASME Transactions on Mechatronics, vol. 25, no. 3, pp. 1479-1486, 2020, ISSN: 00346748.

@article{J20d,

title = {Electrode Configurations for Piezoelectric Tube Actuators With Improved Scan Range and Reduced Cross-Coupling},

author = {D. S. Raghunvanshi and S. I. Moore and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/09/J20d.pdf},

doi = {10.1109/TMECH.2020.2978241},

issn = {00346748},

year = {2020},

date = {2020-06-01},

journal = {IEEE/ASME Transactions on Mechatronics},

volume = {25},

number = {3},

pages = {1479-1486},

abstract = {Piezoelectric force and position sensors provide high sensitivity but are limited at low frequencies due to their high-pass response which complicates the direct application of integral control. To overcome this issue, an additional sensor or low-frequency correction method is typically employed. However, these approaches introduce an additional first-order response that must be higher than the high-pass response of the piezo and interface electronics. This article describes a simplified method for low-frequency correction that uses the piezoelectric sensor as an electrical component in a filter circuit. The resulting response is first-order, rather than second-order, with a cut-off frequency equal to that of a buffer circuit with the same input resistance. The proposed method is demonstrated to allow simultaneous damping and tracking control of a high-speed vertical nanopositioning stage.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

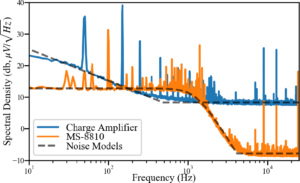

M. G. Ruppert; N. J. Bartlett; Y. K. Yong; A. J. Fleming

Amplitude Noise Spectrum of a Lock-in Amplifier: Application to Microcantilever Noise Measurements Journal Article

In: Sensors and Actuators A: Physical, vol. 312, pp. 112092, 2020, (This work was supported by the Australian Research Council Discovery Project DP170101813).

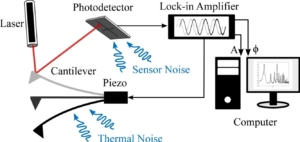

@article{Ruppert2020,

title = {Amplitude Noise Spectrum of a Lock-in Amplifier: Application to Microcantilever Noise Measurements},

author = {M. G. Ruppert and N. J. Bartlett and Y. K. Yong and A. J. Fleming},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/09/J20f.pdf},

doi = {10.1016/j.sna.2020.112092},

year = {2020},

date = {2020-05-29},

urldate = {2020-05-29},

journal = {Sensors and Actuators A: Physical},

volume = {312},

pages = {112092},

abstract = {The lock-in amplifier is a crucial component in many applications requiring high-resolution displacement sensing; it's purpose is to estimate the amplitude and phase of a periodic signal, potentially corrupted by noise, at a frequency determined by a reference signal. Where the noise can be approximated by a stationary Gaussian process, such as thermal force noise and electronic sensor noise, this article derives the amplitude noise spectral density of the lock-in-amplifier output. The proposed method is demonstrated by predicting the demodulated noise spectrum of a microcantilever for dynamic-mode atomic force microscopy to determine the cantilever on-resonance thermal noise, the cantilever tracking bandwidth and the electronic noise floor. The estimates are shown to closely match experimental results over a wide range of operating conditions.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

S. I. Moore; M. G. Ruppert; Y. K. Yong

AFM Cantilever Design for Multimode Q Control: Arbitrary Placement of Higher-Order Modes Journal Article

In: IEEE/ASME Transactions on Mechatronics, pp. 1-6, 2020, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@article{Moore2020,

title = {AFM Cantilever Design for Multimode Q Control: Arbitrary Placement of Higher-Order Modes},

author = {S. I. Moore and M. G. Ruppert and Y. K. Yong},

url = {https://ieeexplore.ieee.org/document/9006926},

doi = {10.1109/TMECH.2020.2975627},

year = {2020},

date = {2020-02-21},

urldate = {2020-02-21},

journal = { IEEE/ASME Transactions on Mechatronics},

pages = {1-6},

abstract = {In the fast growing field of multifrequency atomic force microscopy (AFM), the benefits of using higher-order modes has been extensively reported on. However, higher modes of AFM cantilevers are difficult to instrument and Q control is challenging owing to their high frequency nature. At these high frequencies, the latencies in the computations and analog conversions of digital signal processing platforms become significant and limit the effective bandwidth of digital feedback controller implementations. To address this issue, this article presents a novel cantilever design for which the first five modes are placed within a 200 kHz bandwidth. The proposed cantilever is designed using a structural optimization routine. The close spacing and low mechanical bandwidth of the resulting cantilever allows for the implementation of Q controllers for all five modes using a standard FPGA development board for bimodal AFM and imaging on higher-order modes.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

2019

M. S. Xavier; A. J. Fleming; Y. K. Yong

Image-Guided Locomotion of a Pneumatic-Driven Peristaltic Soft Robot Proceedings Article

In: IEEE International Conference on Robotics and Biomimetics, Dali, Yunnan, China, 2019, ISBN: 1-4244-0570-X.

@inproceedings{C19h,

title = {Image-Guided Locomotion of a Pneumatic-Driven Peristaltic Soft Robot},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/09/C19h.pdf},

doi = {10.1109/ROBIO49542.2019.8961406},

isbn = {1-4244-0570-X},

year = {2019},

date = {2019-12-06},

booktitle = {IEEE International Conference on Robotics and Biomimetics},

address = {Dali, Yunnan, China},

abstract = {In this work, a pneumatic-driven peristaltic soft robot with pressure feedback control and image-guided tracking is developed. Locomotion is achieved in tube-like environments by mimicking the peristaltic motion of earthworms. The soft actuators are made of silicone rubber with 3D molding and fiber reinforcements. Pressure control is performed using custom made syringe pumps and on/off controllers in Arduino. Realtime visual tracking is accomplished in OpenCV with a colorbased approach. The soft robot has a stroke of 30-35mm for each cycle of actuation. This pneumatic soft robot shows great potential for application in minimally invasive surgery due to its compliance and biocompatibility.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

M. S. Xavier; A. J. Fleming; Y. K. Yong

Experimental Characterisation of Hydraulic Fiber-Reinforced Soft Actuators for Worm-Like Robots Proceedings Article

In: International Conference on Control, Mechatronics and Automation, Delft, Netherlands, 2019, ISBN: 978-1-7281-3787-2.

@inproceedings{C19g,

title = {Experimental Characterisation of Hydraulic Fiber-Reinforced Soft Actuators for Worm-Like Robots},

author = {M. S. Xavier and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/05/C19g-reduced.pdf},

doi = {10.1109/ICCMA46720.2019.8988691},

isbn = {978-1-7281-3787-2},

year = {2019},

date = {2019-11-06},

booktitle = {International Conference on Control, Mechatronics and Automation},

address = {Delft, Netherlands},

abstract = {This article describes the design and fabrication of fiber-reinforced soft actuators for a snake-like robot designed to operate inside constrained tubes. The actuators include bending, extension and torsion. These actuators were experimentally characterised using water as the driving fluid with the aid of a water pressure sensor connected to Arduino and video recordings. It is shown that fiber wrapping, geometry of cross-section and elastomer selection are the main parameters affecting the levels of extension, bending and torsion of these actuators. Then, multi-material soft actuators are developed and used to present a soft robot capable of crawling a pipe, a mechanism that could be explored in steerable catheters,endoscopes and pipe inspection devices.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

K. Wang; M. G. Ruppert; C. Manzie; D. Nesic; Y. K. Yong

Scan Rate Adaptation for AFM Imaging Based on Performance Metric Optimisation Journal Article

In: IEEE/ASME Transactions on Mechatronics, 2019, (early access).

@article{Wang2019b,

title = {Scan Rate Adaptation for AFM Imaging Based on Performance Metric Optimisation},

author = {K. Wang and M. G. Ruppert and C. Manzie and D. Nesic and Y. K. Yong },

url = {https://ieeexplore.ieee.org/document/8867937},

doi = {10.1109/TMECH.2019.2947203},

year = {2019},

date = {2019-10-14},

journal = { IEEE/ASME Transactions on Mechatronics},

abstract = {Constant-force contact-mode atomic force microscopy (AFM) relies on a feedback control system to regulate the tip-sample interaction during imaging. Due to limitations in actuators and control, the bandwidth of the regulation system is typically small. Therefore, the scan rate is usually limited in order to guarantee a desirable image quality for a constant-rate scan. By adapting the scan rate online, further performance improvement is possible, and the conditions to this improvement has been explored qualitatively in a previous study for a wide class of possible scan patterns. In this paper, a quantitative assessment of the previously proposed adaptive scan scheme is investigated through experiments that explore the impact of various degrees of freedom in the algorithm. Further modifications to the existing scheme are proposed and shown to improve the closed-loop performance. The flexibility of the proposed approach is further demonstrated by applying the algorithm to tapping-mode AFM.},

note = {early access},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

S. I. Moore; A. J. Fleming; Y. K. Yong

Capacitive Instrumentation and Sensor Fusion for High-Bandwidth Nanopositioning Journal Article

In: IEEE Sensor Letters, vol. 3, no. 8, pp. 2501503, 2019, ISBN: 2475-1472.

@article{Moore2019,

title = {Capacitive Instrumentation and Sensor Fusion for High-Bandwidth Nanopositioning},

author = {S. I. Moore and A. J. Fleming and Y. K. Yong},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2019/10/J19c.pdf},

doi = {10.1109/LSENS.2019.2933065},

isbn = {2475-1472},

year = {2019},

date = {2019-09-09},

journal = {IEEE Sensor Letters},

volume = {3},

number = {8},

pages = {2501503},

abstract = {Precision capacitive sensing methods encode the measurement in a high frequency signal, which requires demodulation. To extract the measurement, the signal is observed over many cycles limiting the bandwidth of the sensor and introducing an undesirable phase lag. To address this limitation, this article outlines a design, which fuses the output of a standard modulated capacitive sensor and a charge amplifier, providing an instantaneous capacitive measurement whose bandwidth is only limited by the speed at which the electronics operate.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

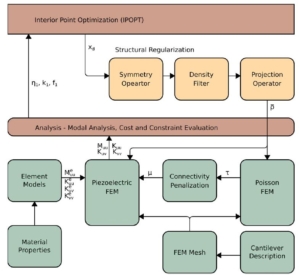

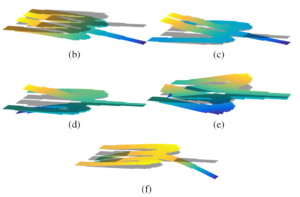

S. I. Moore; M. G. Ruppert; Y. K. Yong

An optimization framework for the design of piezoelectric AFM cantilevers Journal Article

In: Precision Engineering, vol. 60, pp. 130-142, 2019, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@article{Moore2019c,

title = {An optimization framework for the design of piezoelectric AFM cantilevers},

author = {S. I. Moore and M. G. Ruppert and Y. K. Yong},

url = {https://www.sciencedirect.com/science/article/pii/S0141635919302260},

year = {2019},

date = {2019-08-15},

urldate = {2019-08-15},

journal = {Precision Engineering},

volume = {60},

pages = {130-142},

abstract = {To facilitate further miniaturization of atomic force microscopy (AFM) cantilevers and to eliminate the standard optical beam deflection sensor, integrated piezoelectric actuation and sensing on the chip level is a promising option. This article presents a topology optimization method for dynamic mode AFM cantilevers that maximizes the sensitivity of an integrated piezoelectric sensor under stiffness and resonance frequency constraints. Included in the formulation is a new material model C-SIMP (connectivity and solid isotropic material with penalization) that extends the SIMP model to explicitly include the penalization of unconnected structures. Example cantilever designs demonstrate the potential of the topology optimization method. The results show, firstly, the C-SIMP material model significantly reduces connectivity issues and, secondly, arbitrary cantilever topologies can produce increases in sensor sensitivity or resonance frequency compared to a rectangular topology.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

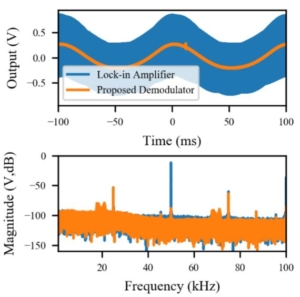

S. I. Moore; M. G. Ruppert; D. M. Harcombe; A. J. Fleming; Y. K. Yong

Design and Analysis of Low-Distortion Demodulators for Modulated Sensors Journal Article

In: IEEE/ASME Transactions on Mechatronics, vol. 24, no. 4, pp. 1861-1870, 2019, ISSN: 10834435, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@article{Moore2019,

title = {Design and Analysis of Low-Distortion Demodulators for Modulated Sensors},

author = { S. I. Moore and M. G. Ruppert and D. M. Harcombe and A. J. Fleming and Y. K. Yong },

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2020/05/J19d-reduced.pdf},

doi = {10.1109/TMECH.2019.2928592},

issn = {10834435},

year = {2019},

date = {2019-07-17},

urldate = {2019-07-17},

journal = {IEEE/ASME Transactions on Mechatronics},

volume = {24},

number = {4},

pages = {1861-1870},

abstract = {System-based demodulators in the form of a Kalman and Lyapunov filter have been demonstrated to significantly outperform traditional demodulators, such as the lock-in amplifier, in bandwidth sensitive applications, for example high-speed atomic force microscopy. Building on their closed loop architecture, this article describes a broader class of high-speed closed-loop demodulators. The generic structure provides greater flexibility to independently control the bandwidth and sensitivity to out-of-band frequencies. A linear time-invariant description is derived which allows the utilization of linear control theory to design the demodulator. Experimental results on a nanopositioner with capacitive sensors demonstrate the realization of arbitrary demodulator dynamics while achieving excellent noise rejection.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

M. Omidbeike; A. A. Eielsen; Y. K. Yong; A. J. Fleming

Multivariable Model-less Feedforward Control of a Monolithic Nanopositioning Stage With FIR Filter Inversion Proceedings Article

In: International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Helsinki, Finland, 2019, ISSN: 978-1-7281-0948-0.

@inproceedings{C19d,

title = {Multivariable Model-less Feedforward Control of a Monolithic Nanopositioning Stage With FIR Filter Inversion},

author = {M. Omidbeike and A. A. Eielsen and Y. K. Yong and A. J. Fleming },

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/02/C19d.pdf},

doi = {10.1109/MARSS.2019.8860974},

issn = {978-1-7281-0948-0},

year = {2019},

date = {2019-07-02},

booktitle = {International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS)},

address = {Helsinki, Finland},

abstract = {A model-less approach for inversion of the dynamics of multivariable systems using FIR filters is described. Inversion-based feedforward techniques have been widely used in the literature to achieve high-performance output tracking. The foremost difficulties associated with plant inversions are model uncertainties and non-minimum phase zeros. Various model-based methods have been proposed to exclude nonminimum phase zeros when inverting both single-input and single-output (SISO), and multiple-input and multiple-output (MIMO) systems. However, these methods increase the model uncertainty as they are no longer exact. To overcome these difficulties a model-less approach using FIR filters is presented. The results when applying the feedforward FIR filter to a multivariable nanopositioning system is presented, and they demonstrate the effectiveness of the feedforward technique in reducing the cross-coupling and achieving significantly improved output tracking.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

M. Omidbeike; Y. K. Yong; S. I. Moore; A. J. Fleming

A Five-Axis Monolithic Nanopositioning Stage Constructed from a Bimorph Piezoelectric Sheet Proceedings Article

In: International Conference on Manipulation, Automation and Robotics at Small Scales , Helsinki, Finland, 2019, ISSN: 978-1-7281-0948-0.

@inproceedings{omidbeike2019axis},

title = {A Five-Axis Monolithic Nanopositioning Stage Constructed from a Bimorph Piezoelectric Sheet},

author = {M. Omidbeike and Y. K. Yong and S. I. Moore and A. J. Fleming

},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/02/C19a.pdf},

doi = {10.1109/MARSS.2019.8860940},

issn = {978-1-7281-0948-0},

year = {2019},

date = {2019-07-02},

urldate = {2019-07-02},

booktitle = {International Conference on Manipulation, Automation and Robotics at Small Scales },

journal = {Int. Conference on Manipulation, Automation and Robotics at Small Scales (MARSS)},

address = {Helsinki, Finland},

abstract = {The paper describes design, modeling and control of a five-axis monolithic nanopositioning stage constructed from a bimorph piezoelectric sheet. In this design, actuators are created by removing parts of the sheet using ultrasonic machining. The constructed nanopositioner is ultra-compact with a thickness of 1 mm. It has a X and Y travel range of 15.5 µm and 13.2 µm respectively; a Z travel range of 26 µm; and a rotational motion about the X-and Y-axis of 600 µrad and 884 µrad respectively. The first resonance frequency occurs at 883 Hz in the Z-axis, and the second and third resonance frequency appears at 1850 Hz, rotating about the X-and Y-axis. A decentralized control strategy is implemented to track Z, θx and θy motions. The controller provides good tracking and significantly reduces cross-coupling motions among the three degrees-of-freedom.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

M. G. Ruppert; B. S. Routley; A. J. Fleming; Y. K. Yong; G. E. Fantner

Model-based Q Factor Control for Photothermally Excited Microcantilevers Proceedings Article

In: Int. Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Helsinki, Finland, 2019, ISSN: 978-1-7281-0948-0, (This work was supported by the Australian Research Council Discovery Project DP170101813).

@inproceedings{Ruppert2019,

title = {Model-based Q Factor Control for Photothermally Excited Microcantilevers},

author = {M. G. Ruppert and B. S. Routley and A. J. Fleming and Y. K. Yong and G. E. Fantner},

url = {https://www.precisionmechatronicslab.com/wp-content/uploads/2021/02/C19b.pdf},

doi = {10.1109/MARSS.2019.8860969},

issn = {978-1-7281-0948-0},

year = {2019},

date = {2019-07-01},

urldate = {2019-07-01},

booktitle = {Int. Conference on Manipulation, Automation and Robotics at Small Scales (MARSS)},

address = {Helsinki, Finland},

abstract = {Photothermal excitation of the cantilever for dynamic atomic force microscopy (AFM) modes is an attractive actuation method as it provides clean cantilever actuation leading to well-defined frequency responses. Unlike conventional piezo-acoustic excitation of the cantilever, it allows for model-based quality (Q) factor control in order to increase the cantilever tracking bandwidth for tapping-mode AFM or to reduce resonant ringing for high-speed photothermal offresonance tapping (PORT) in ambient conditions. In this work, we present system identification, controller design and experimental results on controlling the Q factor of a photothermally driven cantilever. The work is expected to lay the groundwork for future implementations for high-speed PORT imaging in ambient conditions.},

note = {This work was supported by the Australian Research Council Discovery Project DP170101813},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

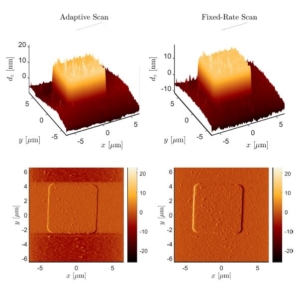

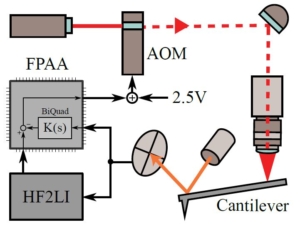

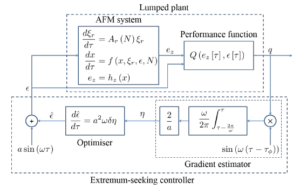

K. Wang; M. G. Ruppert; C. Manzie; D. Nesic; Y. K. Yong

Adaptive Scan for Atomic Force Microscopy Based on Online Optimisation: Theory and Experiment Journal Article

In: IEEE Transactions on Control System Technology, 2019, (accepted for publication).

@article{Wang2019,

title = {Adaptive Scan for Atomic Force Microscopy Based on Online Optimisation: Theory and Experiment},

author = {K. Wang and M. G. Ruppert and C. Manzie and D. Nesic and Y. K. Yong},

url = {https://ieeexplore.ieee.org/document/8643730},

year = {2019},

date = {2019-01-31},

journal = {IEEE Transactions on Control System Technology},

abstract = {A major challenge in Atomic Force Microscopy

(AFM) is to reduce the scan duration while retaining the

image quality. Conventionally, the scan rate is restricted to a

sufficiently small value in order to ensure a desirable image

quality as well as a safe tip-sample contact force. This usually

results in a conservative scan rate for samples that have a

large variation in aspect ratio and/or for scan patterns that

have a varying linear velocity. In this paper, an adaptive scan

scheme is proposed to alleviate this problem. A scan line-based

performance metric balancing both imaging speed and accuracy

is proposed, and the scan rate is adapted such that the metric

is optimised online in the presence of aspect ratio and/or linear

velocity variations. The online optimisation is achieved using an

extremum-seeking (ES) approach, and a semi-global practical

asymptotic stability (SGPAS) result is shown for the overall

system. Finally, the proposed scheme is demonstrated via both

simulation and experiment.},

note = {accepted for publication},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

(AFM) is to reduce the scan duration while retaining the

image quality. Conventionally, the scan rate is restricted to a

sufficiently small value in order to ensure a desirable image

quality as well as a safe tip-sample contact force. This usually

results in a conservative scan rate for samples that have a

large variation in aspect ratio and/or for scan patterns that

have a varying linear velocity. In this paper, an adaptive scan

scheme is proposed to alleviate this problem. A scan line-based

performance metric balancing both imaging speed and accuracy

is proposed, and the scan rate is adapted such that the metric

is optimised online in the presence of aspect ratio and/or linear

velocity variations. The online optimisation is achieved using an